Principles of Total Quality Management (TQM) - How to Use TQM in your Plant?

April 1, 2025

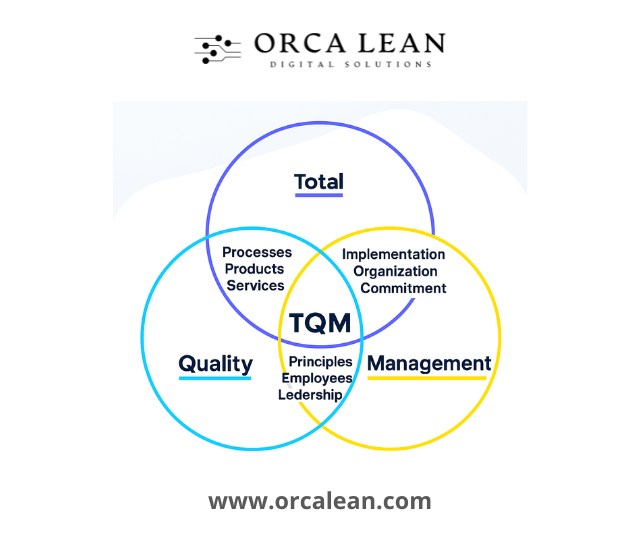

Total Quality Management (TQM) isn’t just another corporate buzzword—it’s a holistic approach that drives long-term organizational success by embedding quality into every aspect of the business. From leadership to frontline workers, TQM creates a culture focused on exceeding customer expectations, improving processes, and empowering employees.

In this blog, we’ll break down the eight core principles of TQM, why they still matter today, and how you can start applying them across your organization.

Why Total Quality Management Still Matters Today?

In an era defined by rapid innovation and fierce global competition, companies can’t afford to treat quality as an afterthought. A single defect, delay, or dissatisfied customer can trigger a domino effect of lost sales, brand damage, and operational inefficiencies. That’s where TQM comes in.

Unlike traditional quality control methods that focus only on the final product, TQM adopts a proactive, organization-wide approach. It embeds quality into every process, from design to delivery, and encourages every employee to think like a quality owner.

TQM is especially vital in today’s digital and lean-driven manufacturing environments. As companies implement new technologies like IoT, AI, and advanced analytics, TQM helps align these tools with a shared goal: creating more value for the customer. Whether you’re reducing defects in manufacturing, improving cycle times, or cutting costs, TQM ensures that your efforts are sustainable and scalable.

In short, TQM is not an old-school philosophy. It’s a future-ready framework for delivering excellence at every touchpoint.

The 8 Core Principles of TQM

Total Quality Management isn’t just theory—it’s the practical backbone of operational excellence. From lean manufacturing floors to digital-first factories, these principles drive consistent results by embedding quality into every process, product, and person.

When combined with structured problem solving and modern manufacturing software, they help teams move faster, make smarter decisions, and reduce waste in manufacturing. Below, we break down each principle with a practical explanation and real-world example.

1. Customer Focus

At the heart of TQM is delivering value that truly satisfies customer needs—whether internal or external. In lean manufacturing, every improvement should ultimately trace back to customer satisfaction. This means understanding their expectations, collecting feedback, and building processes that consistently exceed those expectations.

Example: A precision parts supplier used digital tools to collect and analyze customer complaints. By applying the 5 Whys and structured problem solving, they identified recurring packaging issues, redesigned the workflow, and reduced complaints by 60%.

2. Total Employee Involvement

Everyone in the organization plays a role in quality. When operators, technicians, and team leaders are engaged, trained, and empowered, they actively contribute to identifying problems and improving processes. The Toyota Production System (TPS) embodies this through frontline ownership and daily improvement routines.

Example: A factory team began daily Gemba walks where any operator could raise issues. Using visual boards and manufacturing software, they logged improvement ideas that led to a 15% reduction in downtime in just two months.

3. Process-Centered Approach

Quality is not a coincidence—it’s the output of a controlled and repeatable process. TQM focuses on improving processes first, not blaming individuals. This mindset aligns closely with lean manufacturing, where waste is removed by improving flow and eliminating variation.

Example: A fabrication plant used toyota practical problem solving to map its welding process. With support from digital tools, the team identified redundant checks and simplified the workflow, improving throughput by 20%.

4. Integrated System

TQM requires alignment across the organization—connecting goals, teams, and systems under one quality-driven vision. Manufacturing software now helps integrate functions like maintenance, training, and quality assurance, making collaboration easier and data visible across departments.

Example: A Tier 1 automotive supplier integrated its quality metrics, training records, and audit trails into one platform. This helped reduce quality escapes and eliminated redundant Excel tracking across departments.

5. Strategic and Systematic Approach

Quality isn’t a side project—it’s a strategic initiative that requires long-term commitment. Organizations must link quality goals with business objectives, align teams around them, and execute improvement plans in a systematic way. This principle supports the sustained use of lean and TPS methods.

Example: A plant manager linked first-pass yield targets directly to the company’s cost reduction goals. Using manufacturing software to track progress, the team aligned its Kaizen events around those metrics and achieved a 10% margin improvement over the year.

6. Continual Improvement

Continuous improvement—or Kaizen—is the fuel of TQM. Rather than chasing perfection, teams focus on making small, daily improvements that add up over time. Combined with digital tools and feedback loops, continual improvement becomes part of the organization’s DNA.

Example: A small electronics firm used a digital idea board to capture operator suggestions. After reviewing submissions monthly, they implemented low-cost fixes that saved over $40,000 in labor and materials annually.

7. Fact-Based Decision Making

Gut feeling isn’t enough. TQM insists on using data, trends, and evidence to guide decisions. Tools like the 5 Whys, Pareto charts, and SPC (statistical process control) are essential for root cause analysis toyota and reducing recurring problems.

Example: A packaging plant noticed a spike in defects. Instead of guessing, the team used structured problem solving and data analysis to isolate a raw material batch as the culprit—preventing further losses and improving supplier accountability.

8. Mutually Beneficial Supplier Relationships

Your product is only as good as the materials and components that go into it. TQM promotes close collaboration with suppliers to ensure quality at the source. Shared KPIs, transparent communication, and co-development foster reliability and trust.

Example: A food manufacturer digitized its supplier evaluations and tracked key metrics like defect rates and response time. With this visibility, they engaged suppliers in joint problem solving and reduced ingredient-related issues by 35%.

Common Pitfalls in TQM Implementation

TQM isn’t a plug-and-play solution—it’s a cultural transformation. Many companies struggle not because the principles are wrong, but because of how they’re applied (or not applied).

1. Treating TQM as a One-Time Project: TQM is not a launch-and-leave initiative. One company launched a TQM program with a kickoff event but never followed up with coaching or progress tracking. Without sustained focus, initial momentum faded and quality issues returned within months.

2. Lack of Top-Level Commitment: When leadership doesn’t actively champion quality, employees won’t either. A plant manager who rarely attends quality reviews sends a silent message that it’s not a priority. Without visible commitment, TQM never gains real traction.

3. Poor Communication of Quality Goals: TQM fails when goals live in spreadsheets but never reach the shop floor. For example, if frontline teams don’t understand why reducing changeover time matters, they won’t support improvement efforts—even if it’s tied to lean manufacturing goals.

4. Inadequate Training: Tools like 5 Whys and structured problem solving sound simple—but applying them well takes practice. A team once launched a root cause initiative without proper training, leading to surface-level fixes that never addressed the actual issue.

To learn more about how to train Blue-Collar Workers for enhancing operational efficiency, read our blog.

5. Focusing Only on Tools—Not Changing the Mindset: Digital dashboards and lean boards are helpful, but without a mindset shift, they’re just decoration. One factory installed digital tools to monitor defects but ignored operator input—missing the human element that drives real improvement.

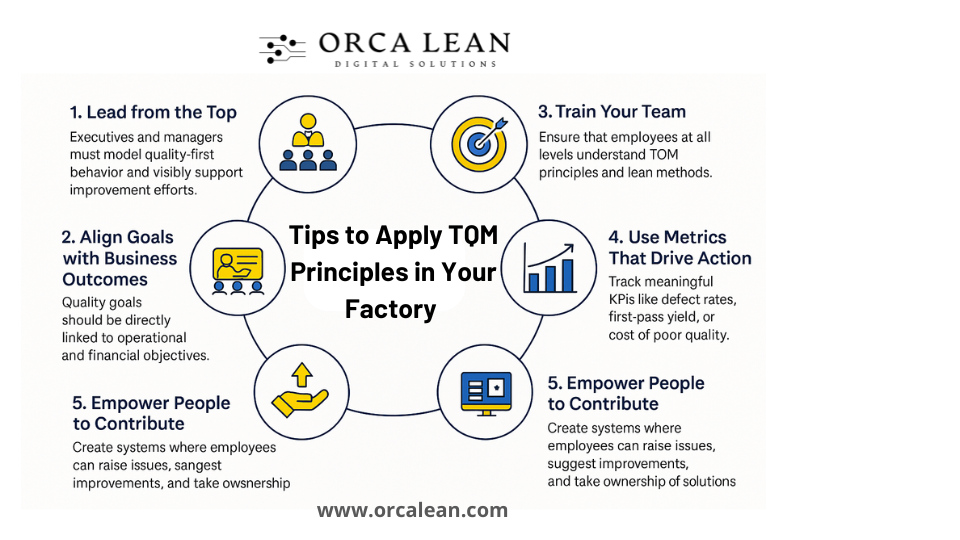

Tips to Apply TQM Principles in Your Organization

Adopting TQM doesn't require a massive overhaul. With consistent leadership, clear priorities, and focused execution, any organization can begin embedding quality into its culture.

1. Lead from the Top - Executives and managers must model quality-first behavior and visibly support improvement efforts. When leadership is engaged, teams follow.

2. Align Goals with Business Outcomes - Quality goals should be directly linked to operational and financial objectives. This ensures that quality improvements drive measurable business impact.

3. Train Your Team - Ensure that employees at all levels understand TQM principles, lean methods, and toyota practical problem solving techniques. Ongoing training builds confidence and capability.

4. Use Metrics That Drive Action - Track meaningful KPIs like defect rates, first-pass yield, or cost of poor quality. Use these metrics not just to monitor performance, but to guide decisions and trigger improvements.

5. Empower People to Contribute - Create systems where employees can raise issues, suggest improvements, and take ownership of solutions. When people feel accountable, they deliver better results.

6. Leverage Digital Tools - Use manufacturing software and real-time dashboards to visualize quality data, escalate problems instantly, and maintain visibility across teams. Digital tools should support—not replace—TQM discipline.

TQM only works when quality becomes part of daily behavior. That’s not about more tools—it’s about building the right habits and backing them with systems that support action.

Conclusion

Total Quality Management isn’t just a framework—it’s a long-term mindset that drives operational excellence, customer satisfaction, and team ownership. By applying its principles consistently, organizations can reduce waste, improve processes, and build a culture of continuous improvement. But implementation requires more than commitment—it needs the right systems.

Solvonext helps manufacturing teams bring TQM to life with structured problem-solving workflows, real-time visibility, and digital tools that connect the shop floor to leadership. Whether you're solving recurring issues or scaling improvement company-wide, Solvonext gives you the foundation to make quality a habit.

Contact us and book your free demo and start the TQM journey today.

Software Solutions for Manufacturing Excellence

Company

Social

Our Contact Info:

Email: contact@orcalean.com

Phone Number: 248 938 0375

Our Offices