Solvonext: Empowering Manufacturers with AI-Driven Problem-Solving

October 10, 2025

In the fast-paced world of manufacturing, operational excellence hinges on the ability to swiftly identify and resolve issues. Solvonext, a cutting-edge problem-solving software, has emerged as a game-changer for manufacturers aiming to enhance efficiency, reduce defects, and optimize workflows.

Recognized by Research.com for its innovative approach, Solvonext integrates AI-driven insights with proven methodologies like PDCA, DMAIC, and 8D to streamline problem-solving processes and drive measurable improvements.

What Is Solvonext?

Solvonext is a comprehensive digital platform designed to facilitate structured problem-solving in manufacturing environments. By embedding methodologies such as Plan-Do-Check-Act (PDCA), Define-Measure-Analyze-Improve-Control (DMAIC), and 8D into a unified workspace, teams can tackle issues methodically and collaboratively.

The platform’s AI capabilities enhance its effectiveness by identifying recurring patterns, predicting potential issues, and suggesting optimal solutions, which allows manufacturers to be proactive rather than reactive.

The software is designed for teams of all sizes, ranging from small factories to large-scale enterprises, and supports complex operations with ease. By unifying problem-solving, documentation, and reporting in one platform, Solvonext ensures that critical information is never lost and that continuous improvement initiatives can be executed efficiently.

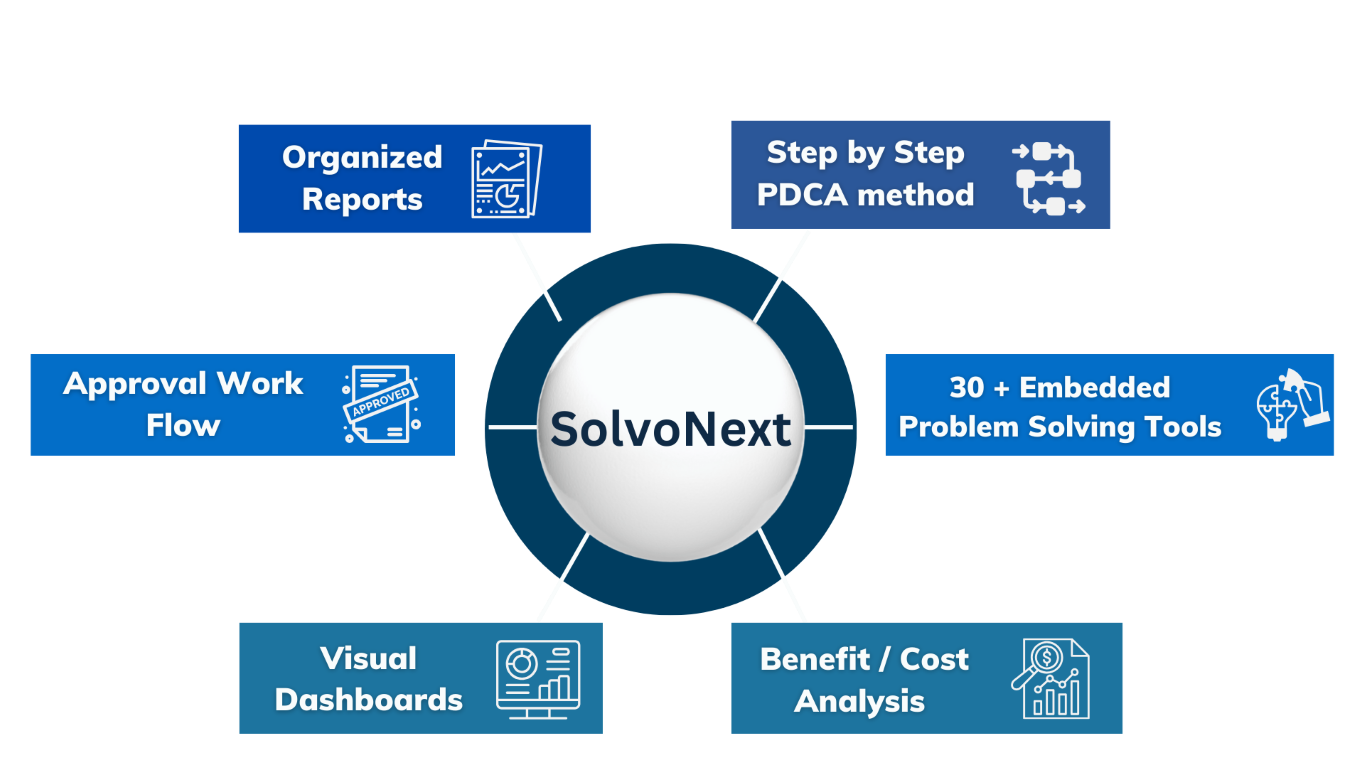

Key Features of Solvonext

1. AI-Powered Root Cause Analysis

Solvonext leverages artificial intelligence to analyze production data and detect the root causes of operational issues. This proactive approach allows teams to address problems before they escalate, reducing downtime and increasing overall productivity. With AI-driven insights, manufacturers can make data-informed decisions and prioritize resources where they have the most impact.

2. Integrated Problem-Solving Methodologies

The platform incorporates several industry-proven problem-solving frameworks, including PDCA, DMAIC, and 8D, providing teams with a structured approach to identify, analyze, and resolve issues. This ensures that solutions are comprehensive, verifiable, and sustainable over time. Teams can choose the methodology that best fits their operational needs, whether they’re tackling minor production inefficiencies or complex systemic issues.

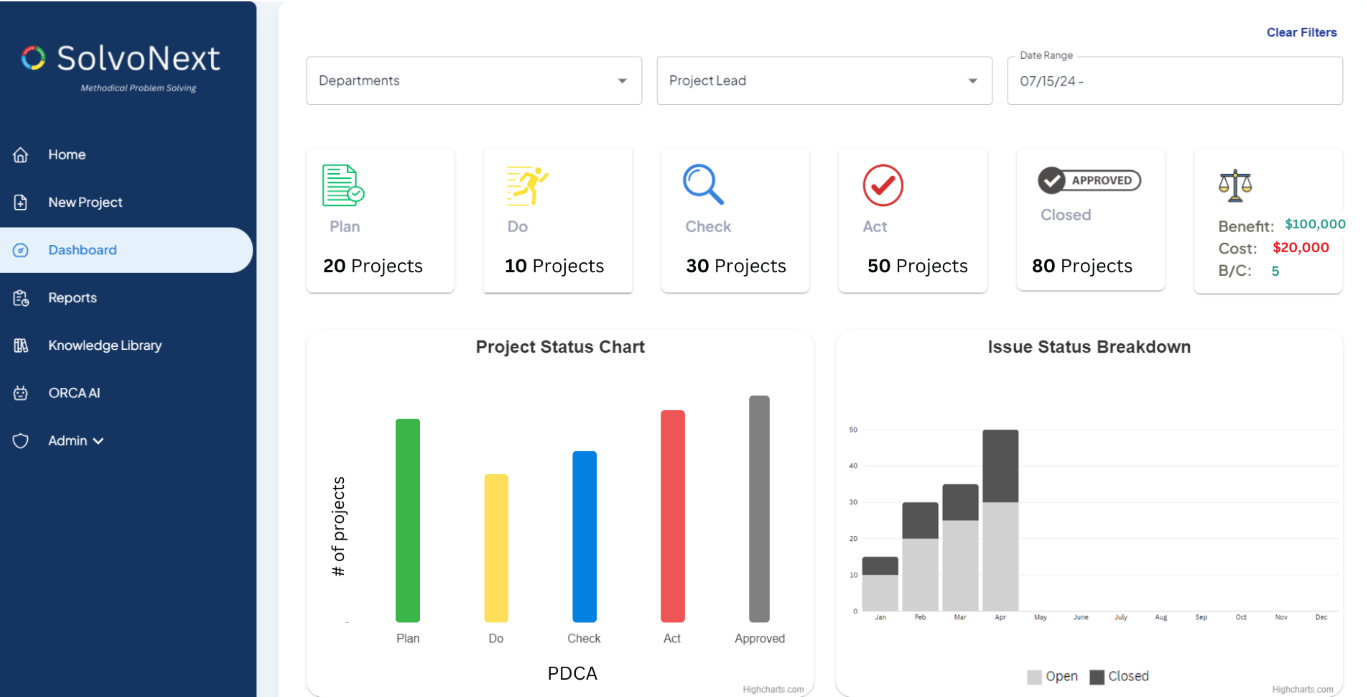

3. Real-Time Dashboards and KPI Tracking

Solvonext offers customizable dashboards that provide real-time visibility into key performance indicators (KPIs). Managers can monitor production metrics, track ongoing improvement projects, and identify bottlenecks instantly. This real-time data empowers decision-makers to respond promptly to operational challenges, ensuring that manufacturing processes remain efficient and optimized.

4. Collaborative Workspace

Designed for teamwork, Solvonext centralizes communication, documentation, and task management. Cross-functional teams can collaborate seamlessly across departments, shifts, or even locations. By having a centralized workspace, manufacturers ensure that all team members are aligned, informed, and engaged throughout the problem-solving process, reducing miscommunication and delays.

5. Automated Reporting and Compliance

The platform automatically generates reports based on ongoing projects and outcomes, enabling managers to evaluate performance without manual intervention. Solvonext also supports compliance with industry standards, ensuring that processes meet regulatory requirements and are ready for audits. This combination of automation and compliance helps manufacturers save time and resources while maintaining high operational standards.

6. API & Third-Party Integrations

Solvonext seamlessly integrates with popular manufacturing and enterprise systems, such as ERP, MES, and analytics tools. This allows organizations to leverage existing infrastructure while enhancing their problem-solving capabilities. Integration ensures that data flows efficiently across platforms, providing a holistic view of operations and enabling faster, more informed decision-making.

Benefits for Manufacturers

Beyond its robust feature set, Solvonext delivers significant business advantages that directly impact operational efficiency, cost management, and continuous improvement.

Enhanced Efficiency

By streamlining problem-solving processes and automating repetitive tasks, Solvonext reduces the time spent on resolving issues. This leads to faster turnaround times, improved production throughput, and higher overall operational efficiency.

Cost Savings

Early identification and resolution of problems help minimize defects, reduce waste, and prevent costly downtime. According to a study by IndustryWeek, poor quality costs manufacturers approximately $50 billion annually in the United States alone. Solvonext’s structured approach helps mitigate these losses and optimize resource allocation.

Continuous Improvement Culture

The platform promotes a culture of continuous improvement by embedding methodologies that encourage regular evaluation, reflection, and corrective action. This cultural shift drives long-term operational excellence and fosters innovation within manufacturing teams.

Scalability

Solvonext is adaptable to various manufacturing environments, making it suitable for both small-scale operations and large enterprises. Its modular design allows organizations to scale functionalities based on their evolving needs, ensuring the platform grows alongside the business.

Improved Collaboration and Communication

With a centralized workspace and collaborative tools, teams can communicate effectively and remain aligned on project goals. This reduces errors, speeds up decision-making, and ensures that improvement initiatives are consistently implemented.

Data-Driven Decision Making

AI-powered insights, combined with real-time dashboards, empower managers to make informed, evidence-based decisions. By understanding patterns, trends, and root causes, organizations can proactively optimize operations and prevent recurring problems.

Industry Recognition

Research.com has highlighted Solvonext as a leading solution in the manufacturing sector, praising its combination of AI-driven insights with traditional problem-solving methodologies. In their assessment, the platform stands out for its ability to integrate structured processes, real-time tracking, and collaboration tools into a single, cohesive platform.

The comprehensive Solvonext review on Research.com details how the platform simplifies complex problem-solving processes while delivering measurable results. The review emphasizes Solvonext’s scalability, usability, and overall impact on manufacturing operations, noting it as an essential tool for companies seeking operational excellence.

Supporting Data and Industry Insights

The adoption of AI and structured problem-solving software in manufacturing is accelerating globally.AI's ability to predict when machinery will fail is one of its most useful applications, according to IBM. It does this by analyzing data from sensors on the machines, which helps companies prevent unexpected shutdowns and save money on maintenance.

Furthermore, the market for manufacturing analytics is expected to grow significantly. It's projected to increase by 15.70% each year, reaching a value of $19.1 billion by 2032. This trend reflects the increasing demand for platforms like Solvonext, which provide actionable insights, facilitate collaboration, and support continuous improvement initiatives.

Why Manufacturers Choose Solvonext

Manufacturers operate in a landscape characterized by tight margins, regulatory requirements, and intense competition. In this context, Solvonext delivers tools that are:

- Reliable: Ensuring high system uptime and secure data management.

- Intuitive: Easy-to-use dashboards and workflows minimize the learning curve for teams.

- Proactive: AI-driven alerts and recommendations help prevent recurring issues.

- Compliant: Supports industry standards and audit-ready documentation.

- Collaborative: Encourages team-based problem-solving and knowledge sharing.

By addressing these critical operational needs, Solvonext enables organizations to achieve higher productivity, lower costs, and enhanced product quality, ultimately strengthening competitiveness in the market.

Final Word

Solvonext stands at the forefront of manufacturing innovation, offering a platform that combines AI-driven insights, proven problem-solving methodologies, and seamless collaboration tools. Its ability to streamline operations, enhance team productivity, and foster a culture of continuous improvement makes it an invaluable resource for manufacturers seeking operational excellence.

Recognition from Research.com reinforces Solvonext’s position as a leading solution in the manufacturing software space. For companies aiming to modernize problem-solving processes and gain a competitive edge, the comprehensive Solvonext review provides detailed insights, expert analysis, and real-world examples of how the platform drives measurable results.

With growing adoption of AI and digital tools in manufacturing, platforms like Solvonext are no longer optional—they are essential for sustainable, data-driven growth and long-term success.

Software Solutions for Manufacturing Excellence

Company

Social

Our Contact Info:

Email: contact@orcalean.com

Phone Number: 248 938 0375

Our Offices