Improve OEE of any Process

Break the Bottlenecks one after the other. Get World Class.

Manage your Process, not the Files. Let Technology do that work.

Too many factories waste time chasing spreadsheets, updating logs, and digging through shared drives instead of actually improving the process. OEE NXT removes that burden by automating data capture, standardizing reports, and giving teams a single source of truth. Instead of managing files, leaders can manage performance—focusing on breaking bottlenecks, reducing downtime, and driving continuous improvement while the system handles the paperwork in the background.

Measure Any Process - Machine, Human or Both

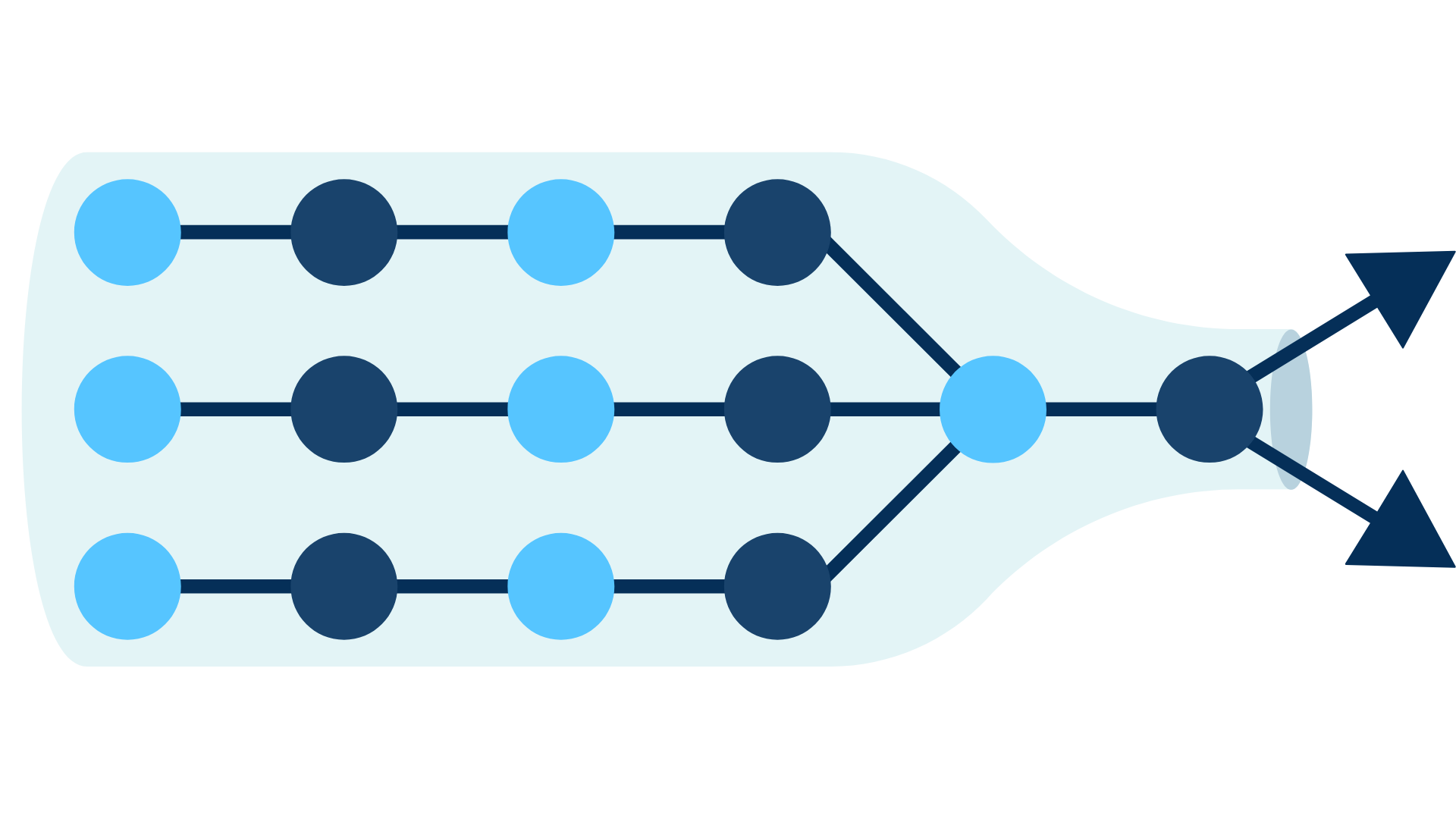

Identify and Break the Bottlenecks Faster

Every factory has a constraint—but once it’s fixed, another takes its place. OEE NXT helps you see bottlenecks shift in real time and equips teams with the tools to eliminate them systematically. By focusing on the biggest loss first, then moving to the next, you create a continuous path of improvement that steadily pushes your OEE toward world-class levels.

Daily Root Cause and Actions for Improvement.

Sustainable OEE gains don’t come from tracking numbers alone—they come from solving the “why” behind losses every single day. OEE NXT captures downtime and defects at the source, then translates them into root causes and clear action plans. Teams walk into each shift knowing not just what went wrong, but exactly what to do next to keep improving.

User-Controlled Analytics.

Instead of waiting on IT or analysts, OEE NXT puts the power of insight directly in the hands of your teams. Operators, supervisors, and leaders can slice data by shift, line, or product in seconds—without coding or complex queries. With flexible, user-controlled analytics, every role gets the answers they need to drive faster decisions and continuous improvement on the floor.

Start Improving OEE immediately. From tracking, data management to improvement everything in one platform.

Software Solutions for Manufacturing Excellence

Company

Social

Our Contact Info:

Email: contact@orcalean.com

Phone Number: 248 938 0375

Our Offices