Qi Screen (AI)

A Touchscreen Software for Smart Factories to help your shop floor teams enter valuable data with ease

Achieve Quality and Continuous Improvement results faster. Ideal for processes that require data inputs from shop floor, such as Quality inspection, Floor Audits, Gemba Walks, Repairs, Six Sigma projects phase and many more

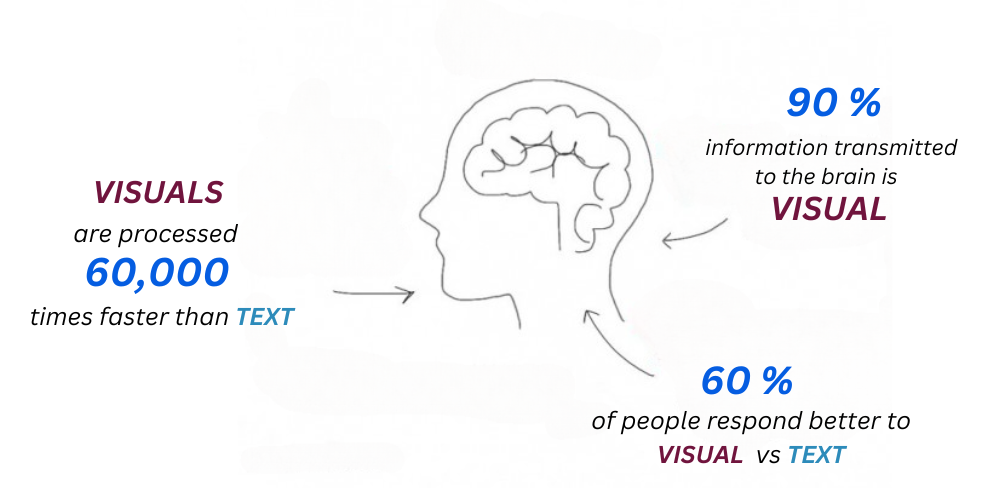

Quality Improvement using the power of Visuals, Problem Details & Insights.

Qi Screen is a digital platform for manufacturing businesses that helps in improving the efficiency of any manufacturing process that requires inputs from humans while ensuring improved operational performance.

It is great for:

Plants that have manual operations andvisual inspections.

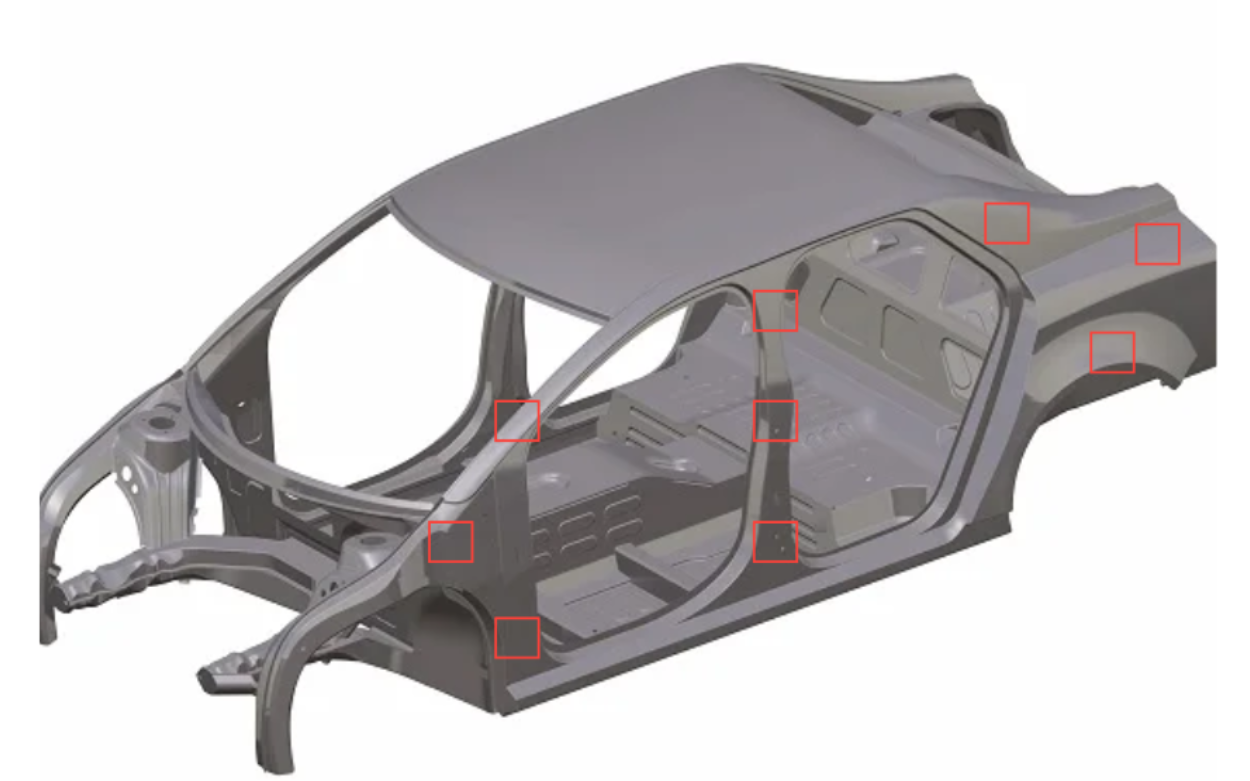

Surface defect inspections in stampings, plastics, Body-in-White (BIW), and paint shops.

Plants that want to capture, track, and share inspection data effectively in factories to improve KPIs like defect rate, inspection time, and first-pass yield faster.

It is most beneficial to :

Quality Managers and Production Managers looking to digitize and streamline inspection processes.

Quality Engineers or problem solvers in factories involved in root cause analysis and corrective actions.

Blue-collar team members, operators, or inspectors performing frontline quality checks.

Use Cases for Manufacturing

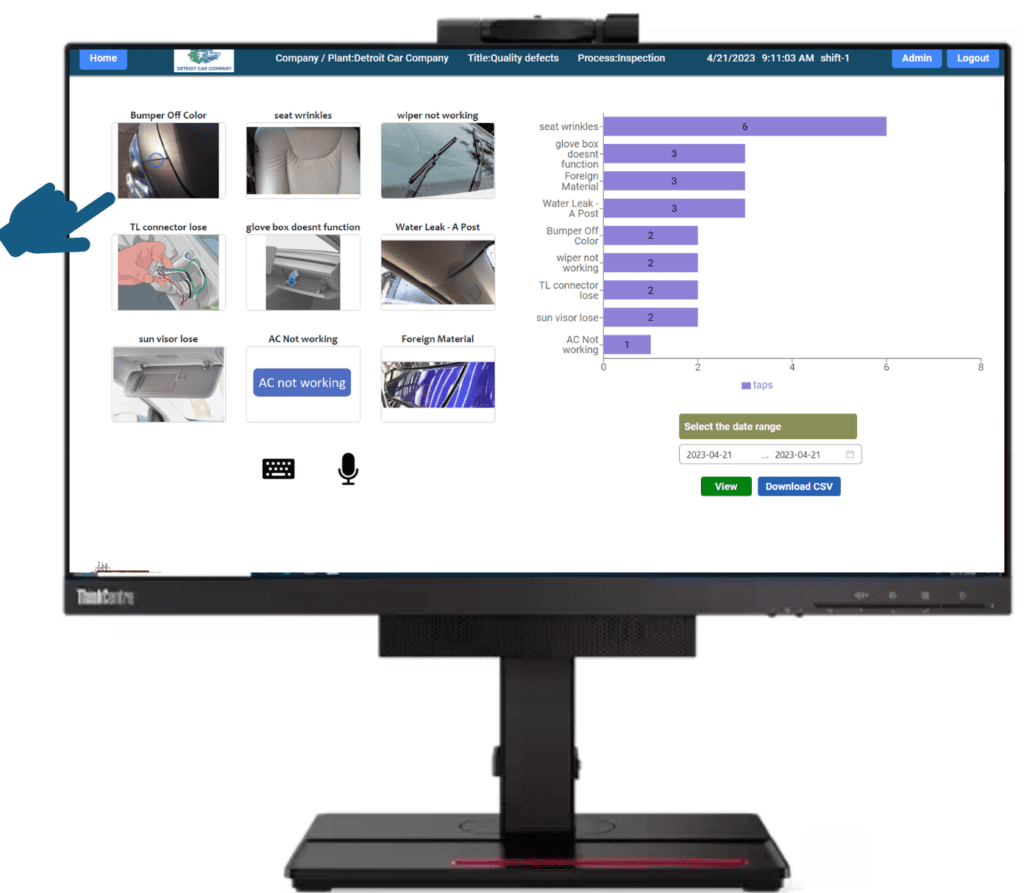

The Qi-screen eliminates manual efforts of frontline shop floor workers to read or type long sentences before data inputs. It saves time, and reduces mistakes often made while capturing valuable data.

Online Inspections

Off Line Inspections

Floor Audits & Gemba walks

Supplier Quality

Six Sigma Projects

Repair Data

( metals, plastics, paint )

Surface Defects

Surface Defects

It's really so simple

Upload Images & enter basic admin details

Use Touchscreen or Mouse Click to Start Capturing Data.

Add detailed comments, type or speak

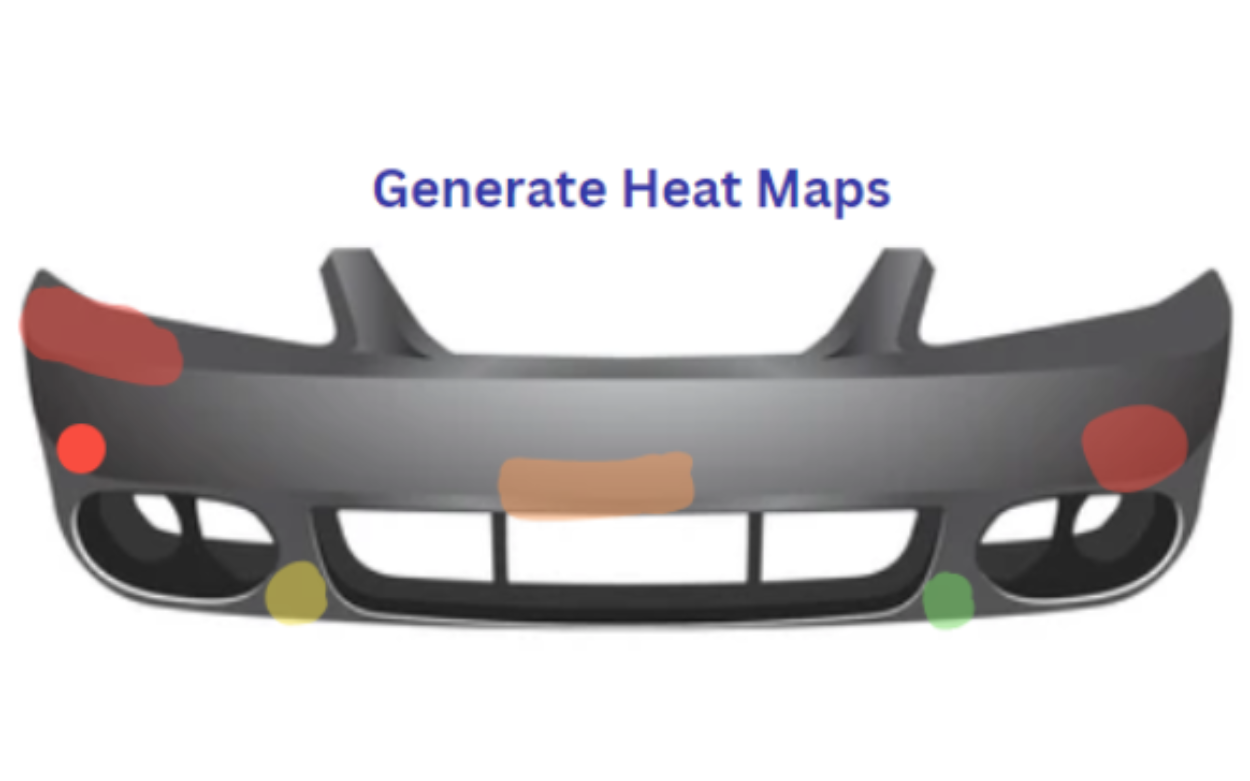

View Live Graphics

Download Historical Data

Ask us about Customizations that work for your plant

High Data Input Accuracy.

Less Mistakes.

Reduced Cycle time.

Capture problems better.

Water leak in the car.

VS

Water leaks inside the car from Left Front A post. It drips

close to the IP dashboard. Its only on MK20 models.

Better Problem Definition.

Solve Problems Faster.

Contain Problems Faster .

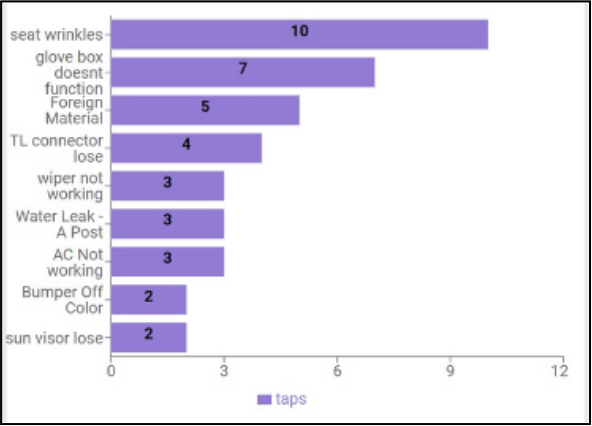

React to Top Problems

Quickly

ORCA AI - tell me about Water leaks ?

Sure ! In the past 3 months, water leaks have been your 3rd largest problem. 80 % of the issues pertain to water leak from A post. 95 % of these A post leaks are on MK 20 models. 50 % of the time its found on Shift 1, 30 % on shift 2 and 20 % in shift 3. The trend is not looking good, in the past 3 months, this problem has increased by 15 %.

Key Insights to make

decisions fast

Faster problem solving

Faster Improvement

Want to Add Detailed Comments? - Type or Speak

Listening to the factory floor is a great idea. Give your operators that flexibility to record what they see. After inputting the manufacturing defect data through a single click or touch, they can either type in more details or they can just use the microphone, and the voice-to-text feature will type the detailed comments for them. The comments will be visible to the operator as he/she types it & will get recorded for a report download. Management or engineers can use this valuable real-time feedback to improve their manufacturing processes, quality inspections, and problem-solving efforts.

Data Input : Metal is damaged.

Detailed Comments :

The metal box has damage on the front right side.

Metal is scratched on the top side, about 2 inches from the black line.

Metal color is coming off.

Etc…

Artificial Intelligence

AI can significantly help you as a Manager or Problem Solver to improve your Plant Metrics. Our goal is to design and customize the manufacturing software system for your specific needs so that you only get the most helpful insights that are relevant to your decision making and problem solving process. We will work with you to understand the objectives and customize the digital factory solution accordingly.

AI applications include pattern recognition, big data synthesis, inference from historical data, advanced process mapping for source identification, predictive analytics, notification, automatic communications, and many more. These capabilities also support defect detection, real-time monitoring, and can be operated through touchscreen software for ease of use by operators on the factory floor.

Pricing

Qi Screen : Standard

Talk to Us

Standard plan gives you all features for managing daily operations and continuous improvement for your shop floor teams. Learning time < 30 mins.

Get a demoFeatures:

- Upto 9 images on single screen

- Role based access control

- Access from anywhere

- Use grouping functions

- Text to speech

- Enter comments for each selection if needed.

- Responsive for most screen sizes

- Admin controlled authorization

- Hardware is not included, see FAQ’s

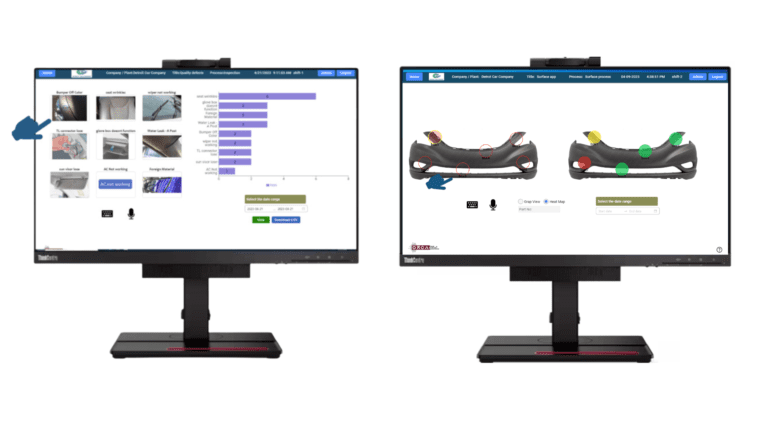

Qi “Surface” : For Surface Inspections

Talk to Us

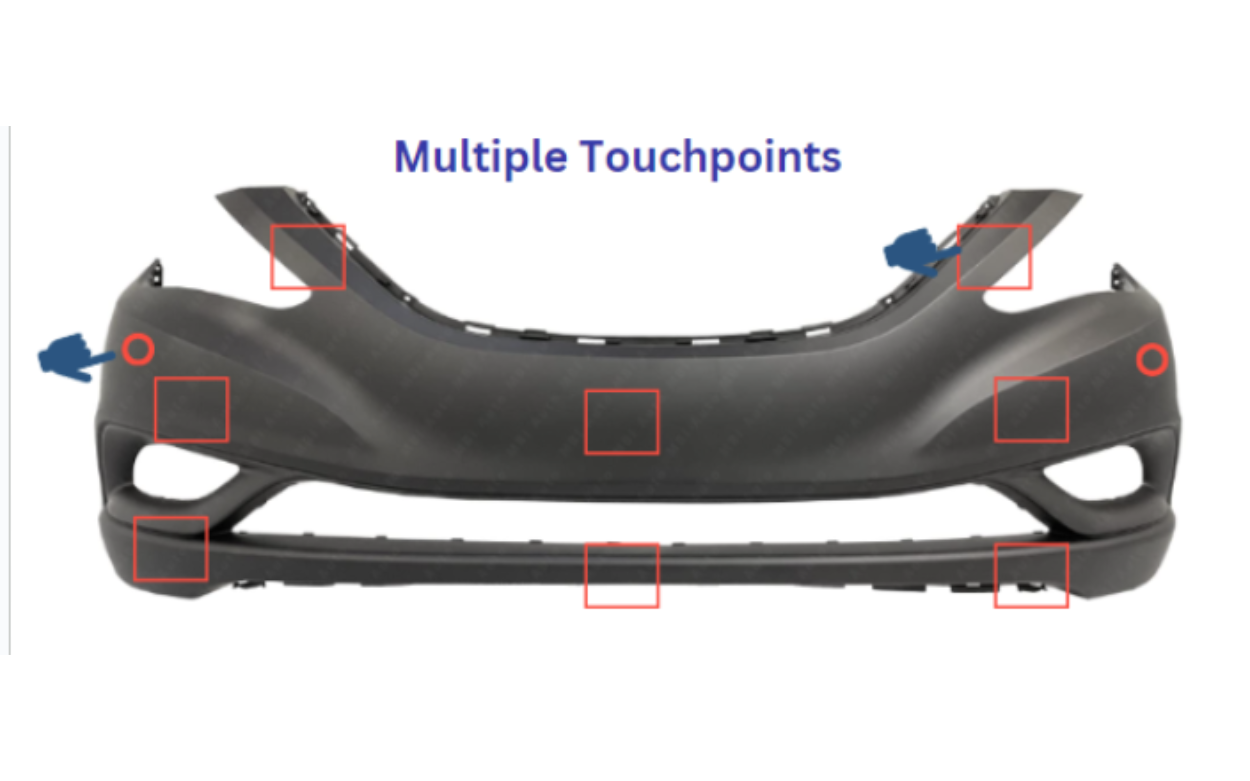

Surface Version allows you to define touchpoints on a part image that you upload. You can also set up defect types and job shifts for data inputs.

Get a demoFeatures:

- Ideal for Inspecting large surfaces and easily data.

- Role based access control.

- Text to speech

- Enter comments for each selection if needed.

- Access from anywhere

- Responsive for most screen sizes but recommended for 21 inch or higher

- Admin controlled authorization

- Hardware is not included, see FAQ’s

Customized / Enterprise

Talk to Us

We can customize the touchscreen software as per the needs of your shop floor use case. Consider adding multiple screens, more images, escalation process, internal chats, alerts and notifications and many more features.

Get a demoFeatures:

- Fully Custom features while maintaining the same touchscreen capabilities.

- Customized deployment - your on premise server or your preferred company cloud, or a hybrid model.

- We work with you to understand your objectives, design and develop the software as per your needs.

- Talk to us to learn more

Choose the Deployment Options based on your Company Policies

ORCA LEAN Standard AWS Deployment

Deploy in your Company's On Premise Server

Deployment in your Company's Cloud

We understand and respect the fact that every plant has different challenges, organizational structure and culture. We will work with you to understand your requirements and customize Qi Screen to best fit your needs. It is our goal to help you in your improvement initiatives for successful results.

Software Solutions for Manufacturing Excellence

Company

Social

Our Contact Info:

Email: contact@orcalean.com

Phone Number: 248 938 0375

Our Offices