FASTER AND ORGANIZED PROBLEM SOLVING

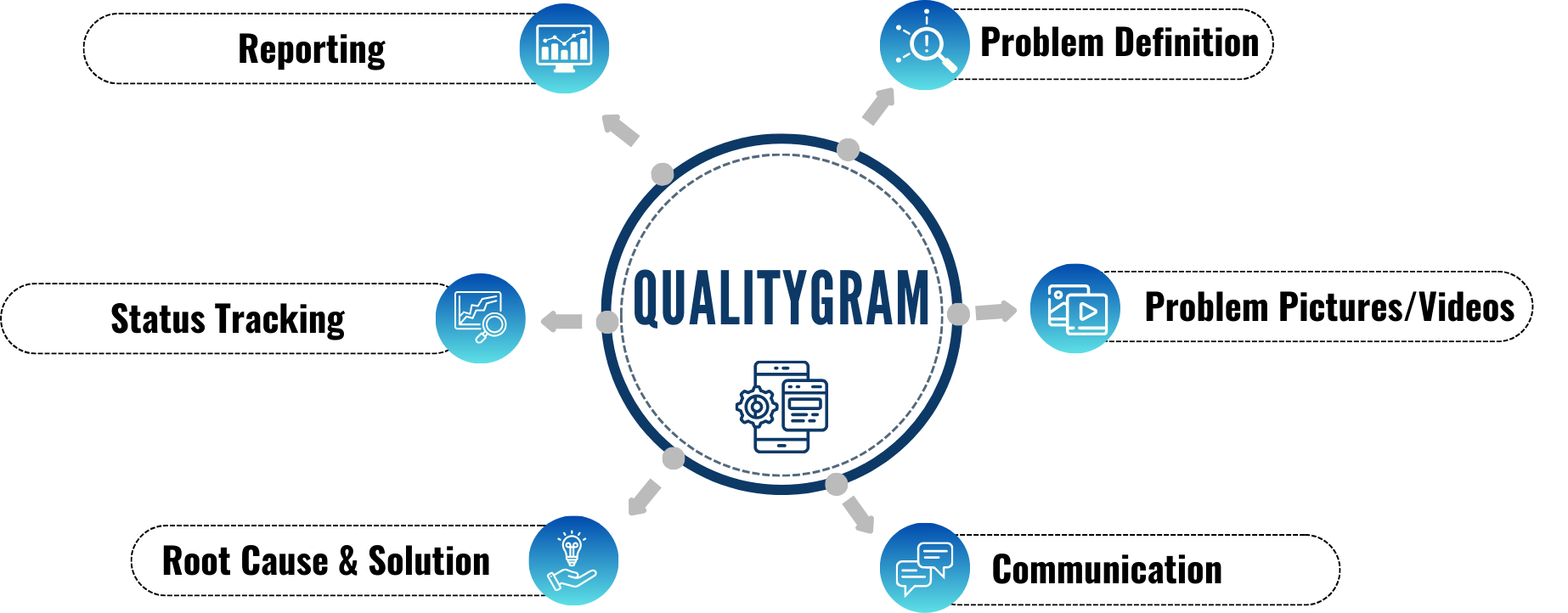

Qualitygram is a Smart Manufacturing Solution that helps manufacturing plants solve problems faster in order to get speedy gains in KPIs ( key performance indicators ). It is also a Management Tool for Leaders & Managers to drive Continuous Improvement at high pace in an organized way.

An Advanced Mobile and Web Application to Manage Problems Centrally & Get Faster Problem Solving.

Reduce the time between Issue Discovery and Issue Resolution.

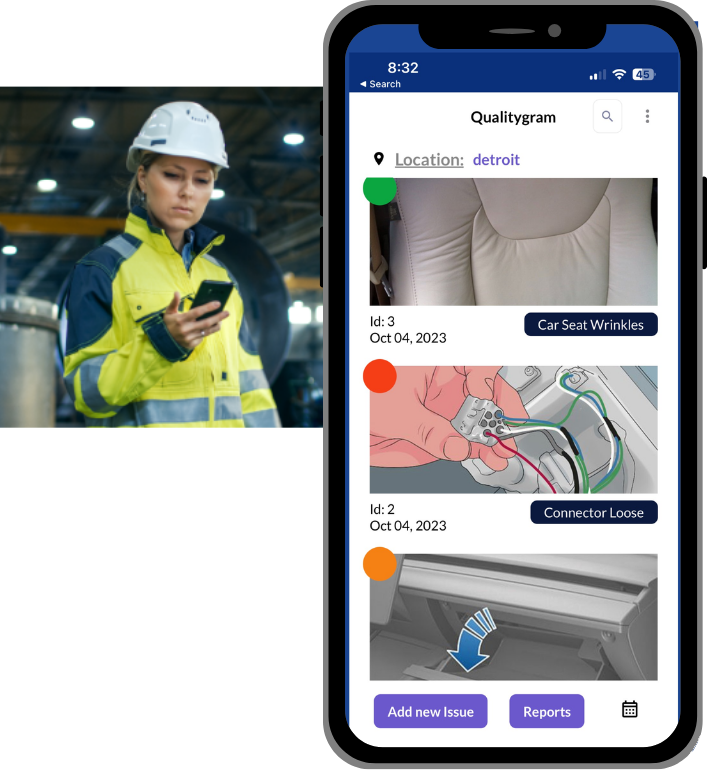

Empower your team to initiate problems and engage in problem solving instantly from wherever they are. Qualitygram, an efficient lean problem solving software for factories can be used for Gemba Walks where you log issues as soon as you find them or if you are off site at a supplier, OEM or a dealership. The instant capture, share and track features eliminate multiple email and text messages while also minimizing human errors which can be a result of manual entries.

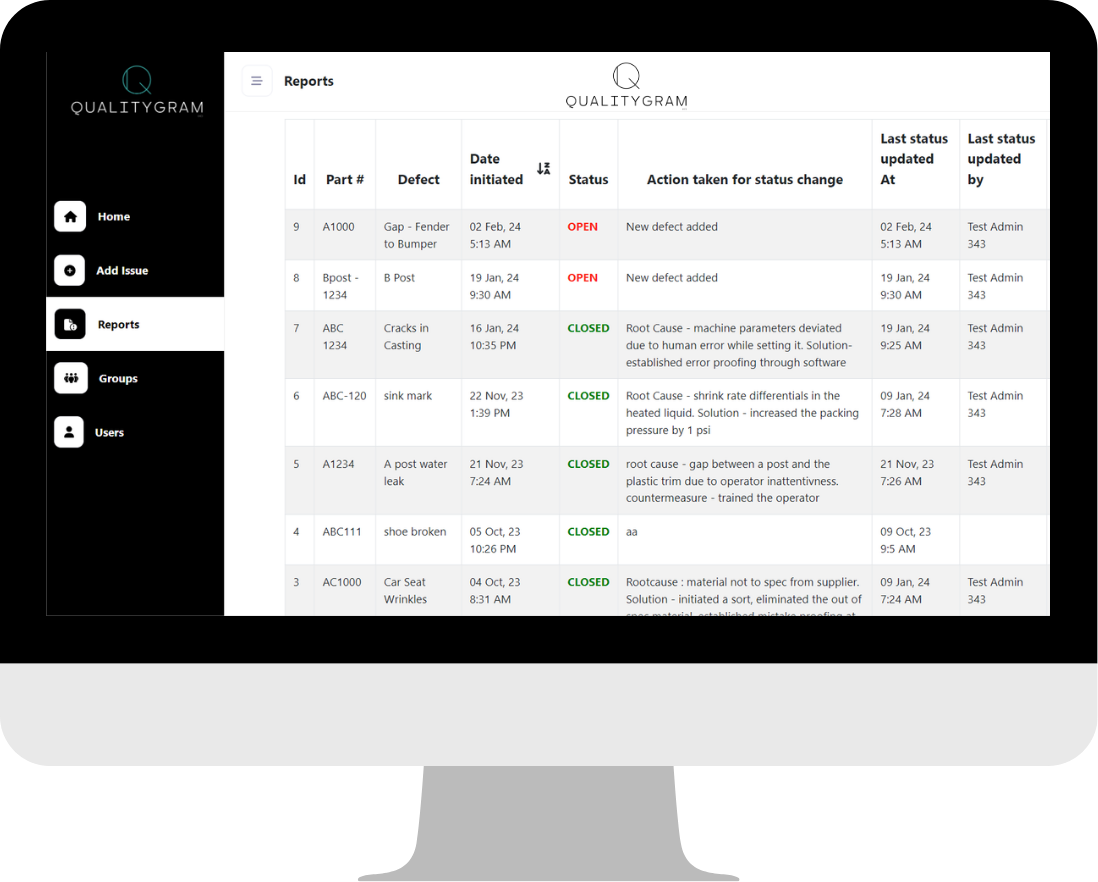

Clear Web Reports to keep everyone on Track and have Effective Meetings

Qualitygram web application allows you to view more detailed factory reports and easily access each issue in detail, which makes navigating from issue to issue a breeze in the meetings, saving a lot of your valuable time. Qualitygram is a great management tool to keep things on track and solve problems faster.

QUALITYGRAM: Real-World Problem Solving for Manufacturing Teams

Faster Problem Solving

Quickly raise issues using your smartphone. Track updates, collaborate in real-time, and close problems faster. Eliminate delays and reduce downtime.

Instant Team Engagement

Tag teams or groups, notify them instantly. Share ideas, photos, videos, and chat directly in the app. Keep everyone aligned, informed, and working together.

Knowledge Retention

Capture and analyze root causes, corrective actions, and lessons learned. Reuse this knowledge for recurring problems, new product launches, and preventive actions.

Clear Communication

Ditch messy emails, long threads, and scattered messages. Use one platform to simplify communication—fast, clear, and clutter-free.

Discipline & Culture

Drive a culture of continuous improvement in factories. Set clear expectations, track progress live, and build accountability through notifications and visibility.

Mobile & Accessible

Support your frontline teams. Qualitygram works on the go—anytime, anywhere. Empower your workforce to act fast and solve problems in real time.

Manage Problems during New Product or Process Launch

A typical product launch or process launch experiences 3 to 5 times more problems than stable production. QUALITYGRAM helps you manage launch issues effectively by instantly engaging cross-functional teams and driving problems to closure—faster.

No more juggling paper forms, Excel files, or scattered photos. QUALITYGRAM is an all-in-one problem-solving platform that keeps everything organized, centralized, and easy to track in real time.

Improve Manufacturing KPI Faster with Qualitygram

As you solve problems faster, KPI metrics will also improve faster. Typically, a standard Kaizen or continuous improvement project takes between 0 to 30 days to solve, an intermediate takes between 30 to 60 days, and complex problems take more than 90 days to solve.

Once an organization knows how to improve this pace, they see a real uptick in their KPI improvements like quality, productivity, efficiency, and delivery performance. Qualitygram is a useful management tool for leaders and managers to keep the team engaged, accelerate problem resolution, and achieve those KPI improvements faster.

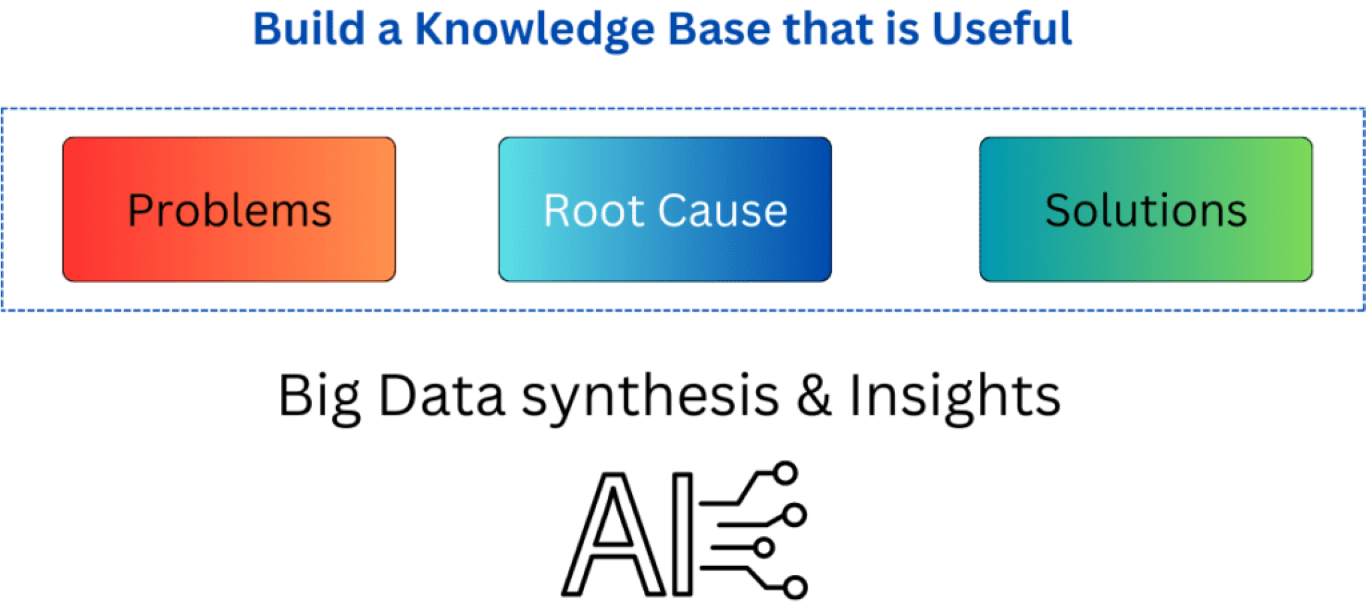

Artificial Intelligence

Our manufacturing software is at the forefront of AI integration, leveraging advanced technologies such as Large Language Models (LLMs) and Natural Language Processing (NLP) to transform how data is interacted with and analyzed on the shop floor. With optional AI capabilities, users can input data and soon engage in natural language conversations with our software. This AI-driven interface supports real-time querying and deep analysis, providing tailored insights through an intuitive, conversational user experience.

Our Software plays a crucial role in capturing and analyzing experience based knowledge from retiring employees, preserving essential insights and techniques. This structured knowledge is then made accessible to new staff, ensuring continuity and maintaining operational excellence as workforce demographics evolve. Choose our AI-enhanced manufacturing software for a safe, reliable, and insightful addition to your operational toolkit, ensuring that your shop floor remains innovative and competitive.

Pricing

Standard

$699 /Month

Standard plan includes mobile and web applications for floor teams. Learning time < 30 mins.

Get a demoFeatures:

- Mobile Application secured access

- Web application secured access

- Initiate Issues, barcode scanning, add part numbers and defect names

- Use grouping functions

- Chat with your Teams about specific issues as you solve them

- Reports

- Live feed for issue management

- Email and push Notifications

- Role based access control

- Access to multiple plants within same company, authorization controlled by your admin

AI (Artificial Intelligence)

Get a quote

Standard features plus Artificial Intelligence large language model integrated for insights and analysis.

Talk to usFeatures:

- All Standard Features included.

- Data synthesis and analysis with AI.

- Chat with AI and ask any questions regarding the data, comments or any information you have saved in Qualitygram for your plant.

- Build a knowledge library of root cause and corrective actions.

Customized / Enterprise

Get a quote

Customized version as per your needs and specific plant use case. Enterprise deployment as per your requirements.

Talk to usFeatures:

- Customized Features.

- Customized deployment - your on premise server or your preferred company cloud, or a hybrid model.

- We work with you to understand your objectives, design and develop the software as per your needs.

- Talk to us about enterprise solution, for multiple plants / locations / changes in user management or any other requirements.

Choose the Deployment Options based on your Company Policies

ORCA LEAN Standard AWS Deployment

Deploy in your Company's On Premise Server

Deployment in your Company's Cloud

We understand and respect the fact that every plant has different challenges, organizational structure and culture. We will work with you to understand your requirements and customize our smart factory software solutions to best fit your needs. It is our goal to help you in your improvement initiatives for successful results.

Software Solutions for Manufacturing Excellence

Company

Social

Our Contact Info:

Email: contact@orcalean.com

Phone Number: 248 938 0375

Our Offices