SolvoNext - NCR CAPA

Digitize your NCR (non-conformance reporting) & CAPA (corrective and preventive actions) process and Reduce Cost of Poor Quality (COPQ).

A well organized step by step management of NCR CAPA using embedded smart factory tools, root cause analysis and action items with visual dashboards and automated reports.

Empowering Small & Medium Factories - Go Digital with NCR CAPA

Solvonext NCR CAPA is a manufacturing software that replaces paper driven processes of documenting non conformances and corrective & preventive actions in manufacturing. This NCR CAPA software for factories is carefully designed to ensure that Shop Floor Teams from Production, Quality and other departments can easily adopt digital transformation and collaborate to solve problems methodically while preserving knowledge base.

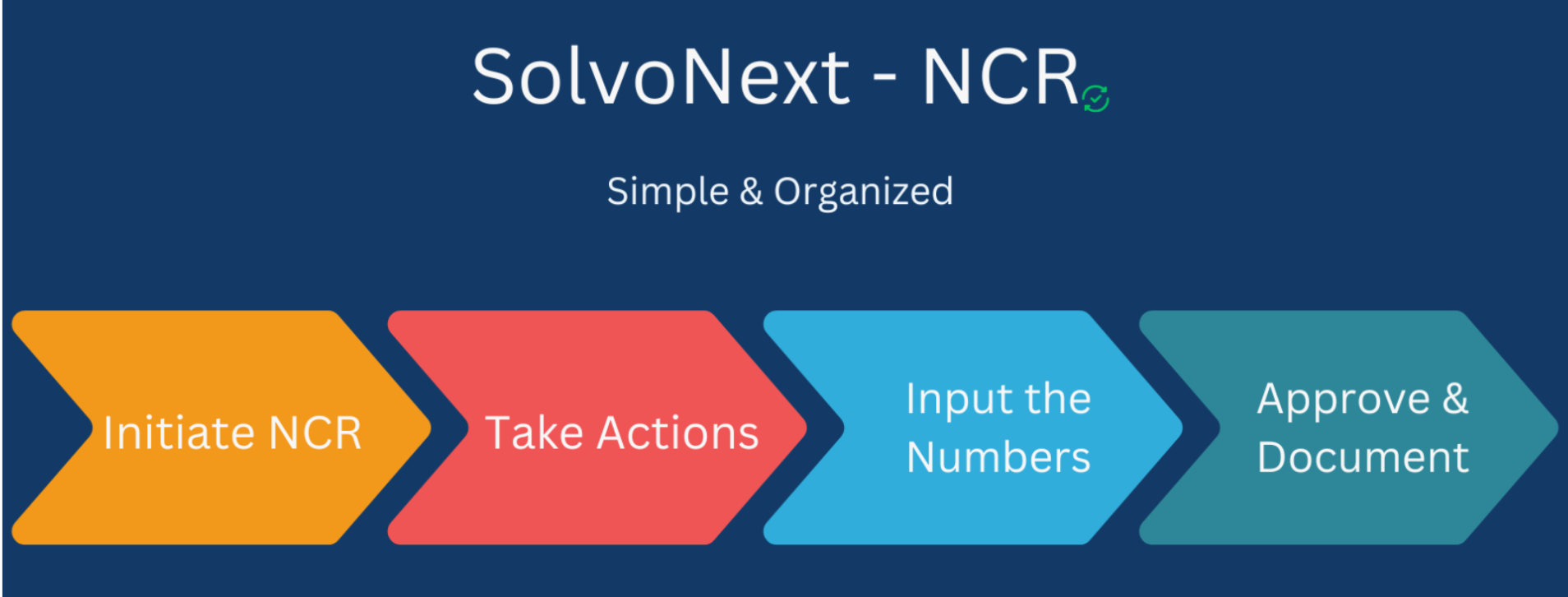

Simplified 4 Step Method to NCR CAPA

Solvonext NCR CAPA is built on following steps :

Initiate NCR and notify the concerned team members to take containment actions.

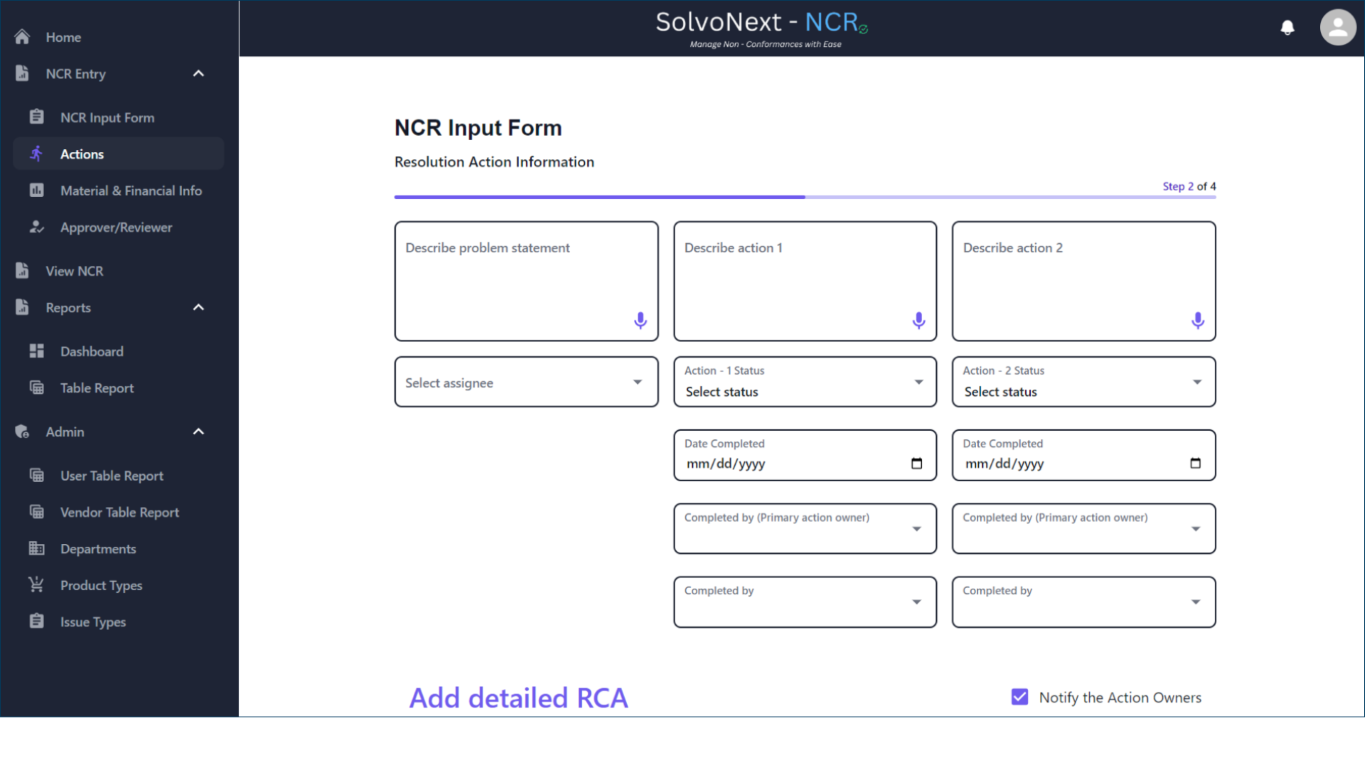

Perform root cause analysis in plant and CAPA ( corrective and preventive actions ). Use the embedded tools for ease.

Input the numbers - record all financial information and information about responsible parties.

Validate the documentation and approve. Save and retrieve as needed in the reports section.

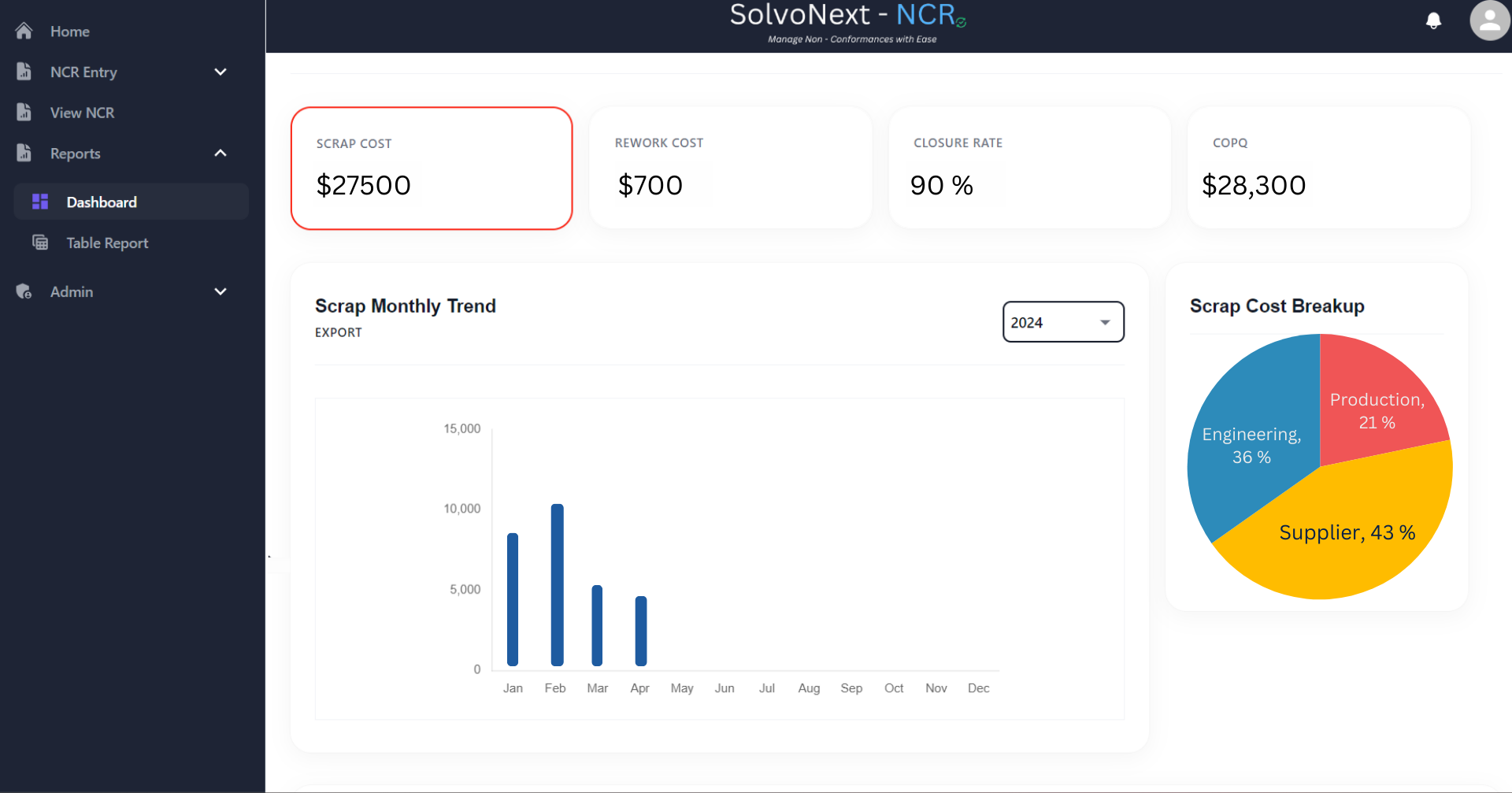

Dashboard & Reports

Solvonext eliminates human errors by replacing the need of managing Excel files, storing them, and sharing them. It provides:

Automated charts and graphs

Tracking by Departments

Monthly Progress Tracking

Reports to see NCRs (Non-Conformity Reports) by status such as Open, Closed, Rejected

COPQ (Cost of Poor Quality) is a great way to track and understand the financial impact of manufacturing quality issues, process inefficiencies, and production waste. Solvonext allows you to input labor rates, material costs, and several other parameters to calculate total COPQ easily and accurately.

With its real-time dashboards for factories, data-driven insights, and custom reports, Solvonext helps quality teams, plant managers, and continuous improvement leaders make faster, smarter decisions and drive down quality-related costs.

Approval Flows and Notifications

Quality Improvement is dependent on a disciplined process and organized approach towards finding and solving problems in smart factories. A streamlined digital process increases transparency and allows for faster and more clear communication between the team members. Solvonext is also built with a vision to be used as an effective digital tool for streamlined cross-functional communication as well as with external parties with authorized access.

Keep the team on Track with Automated notifications and Easy Management to communicate to relevant team members for specific NCR's. Set up approvers and role based access, Approve, Reject or Edit the NCR easily.

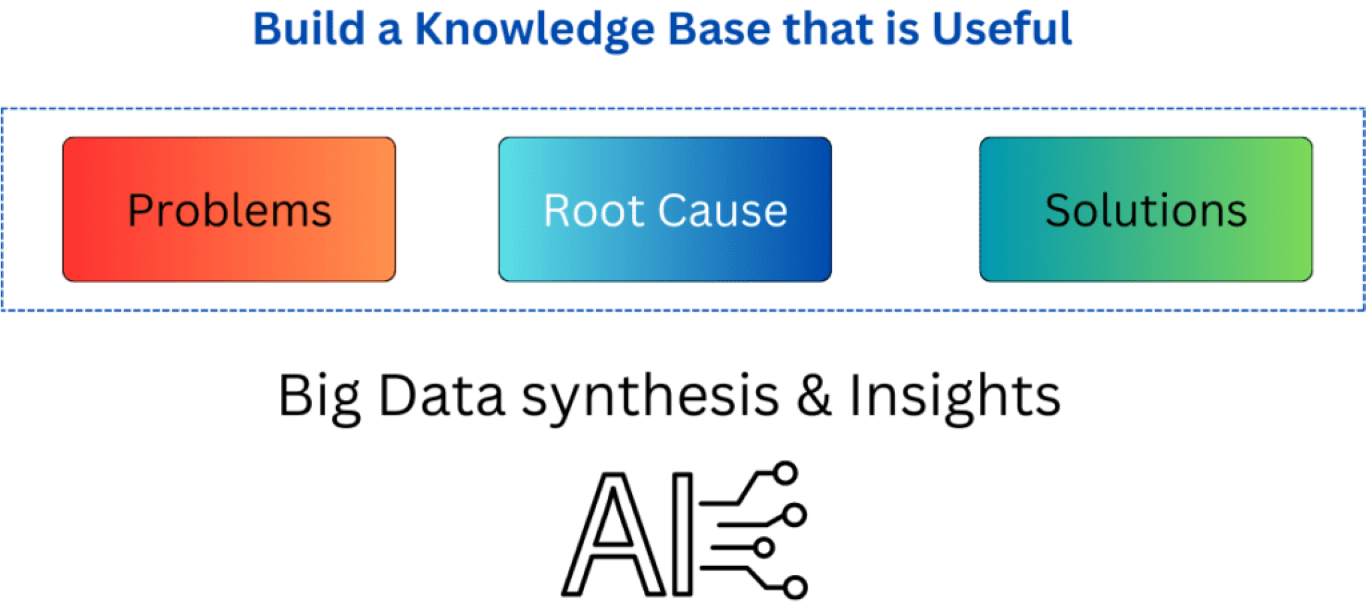

Artificial Intelligence ( optional )

AI can be very useful to you as a Manager or a Problem Solver. Our goal is to customize industry 4.0 software solutions for your specific needs so that you only get the most helpful insights that are relevant to your decision making and problem solving process. Some examples include Pattern recognition, Diagnostic analytics, Descriptive analytics, Predictive Analytics, Big Data Synthesis, Inferences, Advanced Process Mapping for Source identification, Automatic communications and many more.

Pricing

Standard

Get a quote

Standard plan includes an advanced NCR CAPA web software for your company.

Get a demoFeatures:

- Web application secured access

- Mobile responsiveness

- Step by Step NCR & CAPA process

- Embedded 5 why and Fishbone

- Upload your document capabilities

- Visual Dashboard & Tracking

- Digital Reports

- Printable Reports

- Approval Flow

- COPQ tracking

- Email notifications and Alerts

- Role based access control

- High Security protocols

AI (Artificial Intelligence)

Get a quote

Standard features plus Artificial Intelligence large language model integrated for insights and analysis.

Get a demoFeatures:

- All Standard Features included.

- Data synthesis and analysis with AI.

- Chat with AI and ask any questions regarding the data, comments or any information you have saved in Qualitygram for your plant.

- Build a knowledge library of root cause and corrective actions.

Customized / Enterprise

Get a quote

Customized version as per your needs and specific plant use case. Enterprise deployment as per your requirements.

Get a demoFeatures:

- Customized Features.

- Customized deployment - your on premise server or your preferred company cloud, or a hybrid model.

- We work with you to understand your objectives, design and develop the software as per your needs.

- Talk to us about enterprise solution, for multiple plants / locations / changes in user management or any other requirements.

Choose the Deployment Options based on your Company Policies

ORCA LEAN Standard AWS Deployment

Deploy in your Company's On Premise Server

Deployment in your Company's Cloud

We understand and respect the fact that every plant has different challenges, organizational structure and culture. We will work with you to understand your requirements and customize SolvoNext NCR CAPA to best fit your needs. It is our goal to help you in your improvement initiatives for successful results.

Software Solutions for Manufacturing Excellence

Company

Social

Our Contact Info:

Email: contact@orcalean.com

Phone Number: 248 938 0375

Our Offices