Enable your Shop Floor with a System to achieve Standardized Work.

Give your Organization not just a tool but a set of standard work procedures to achieve the benefits of Standardized Work which forms the basis of High Quality Consistent Production. The goal of every plant is to ensure the work gets done with every step reducing human error at the right time in the right way. Standard Work Pro allows you to have a smooth and structured workflow of documents and videos creation and managing them in a secured way.

An Organized Standard Work System to give Stability to your Operations

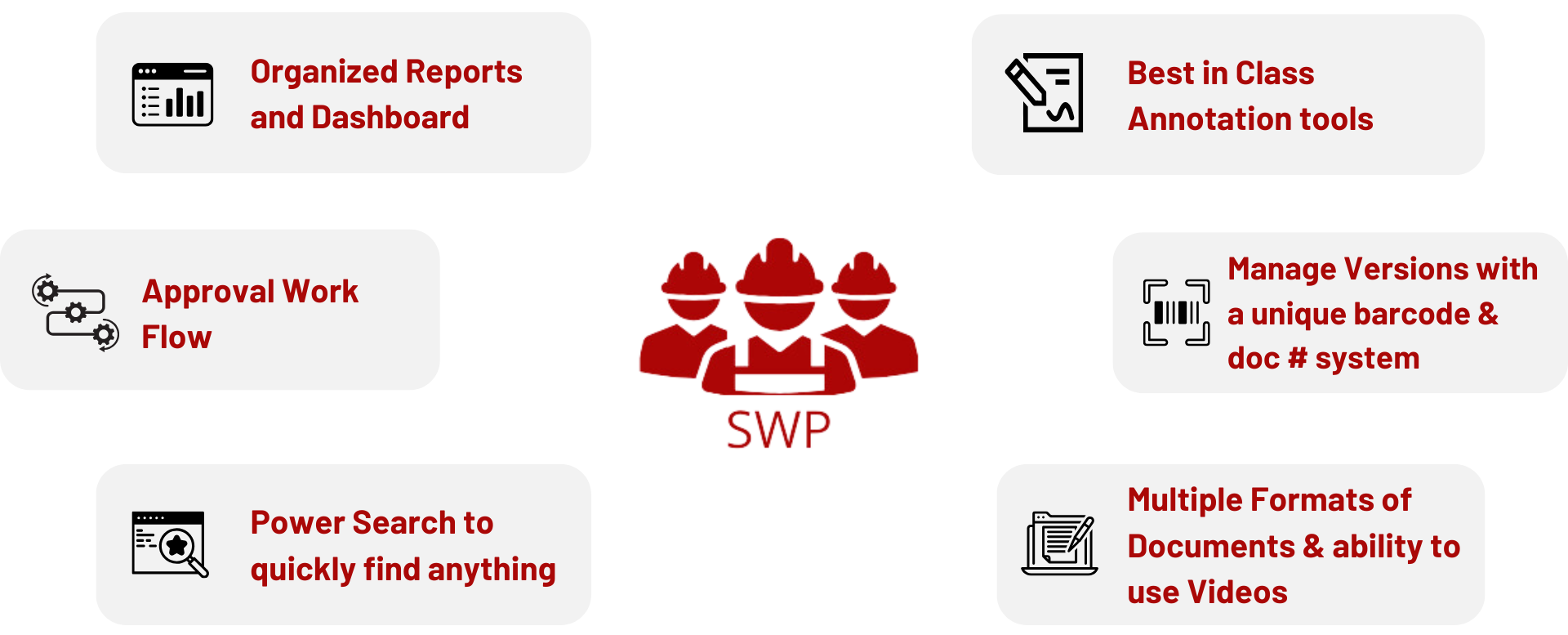

Standard Work Pro Offers Multiple Documentation formats

Standard Work can be created with various forms of documents for different purposes. The key is to be consistent once you choose the type of document for a specific purpose. For example, you may not need a long format document for a simple Quality alert, but for an entire process you need a long form step by step document.

That's why we embedded various formats into our program. You can now choose which type of document to leverage the benefits of paperless standard work documentation. Our lean manufacturing standard work software allows you to be efficient at all steps of creating and managing the work instructions.

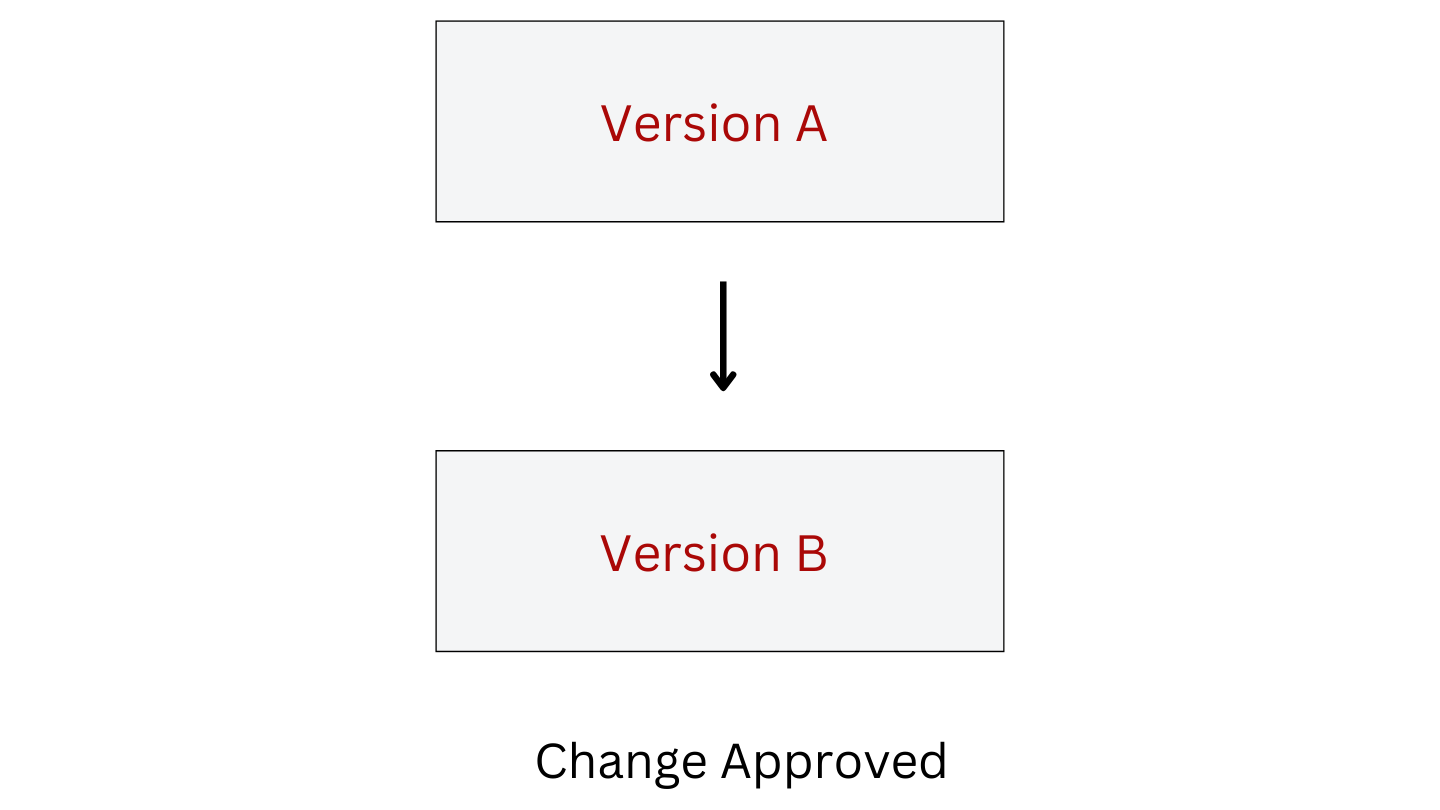

Change Management - A Critical Consideration

Manufacturing Plants have done Standardized Work instructions forever, using power point, word, excel or their own legacy system. However, the most crucial aspect of good standard work in lean manufacturing is “change management”. Every time there is a change in the standard work procedure, it either never gets updated in the document or there is often a confusion about which document on the shop floor is to be trusted. Also oftentimes the documents are not authorized by key people before they are used to run the operations.

Standard Work Pro gives you a very easy workflow to manage versions, audit your shop floor and approve / reject the procedures.

Standard Work Pro Enables you to Run your Production with High Quality

Standard Work Creation

Creating various types of standard work documents is very simple and easy. We made it friendly for people who are not computer savvy. Use the easy Annotation tools and create and describe important points on the images.

Change Management

An important aspect of stability in the manufacturing production, we kept change management very simple to follow for any organization. Approve / reject, revise, scan the barcodes and ensure everything being accessed is correct leading to great results.

Access

As the plants become more tech friendly, standard work is also accessible in the mobile friendly view on ipads and smartphones. Authorized Access is needed so you can be rest assured that your data is seen by only authorized people.

Power Search

Have thousands of documents and want to find a specific one? We integrated a power search feature, now you can quickly find the required standard work instruction you are looking for and access it instantly. Use it while solving problems, in the 3G Gemba walks, or as an important part of line balancing.

Authorization Levels

Standard Work Pro comes with authentication levels which are controlled by your assigned admin. This ensures that different levels of organization get view, edit or manage access according to their job roles. Admin controls within the standard work software keep things secured as well as flexible as needed so your production keeps running as per your needs.

People Training

People Training without good Standard Work can be very harmful to an operation. We paid attention to this, so your supervisors can easily print or quickly pull up the work instructions and share with a new employee under training for the job. Take your new employees through every step of the process in a quick and easy way for best results.

Why does Standard Work matter so much ?

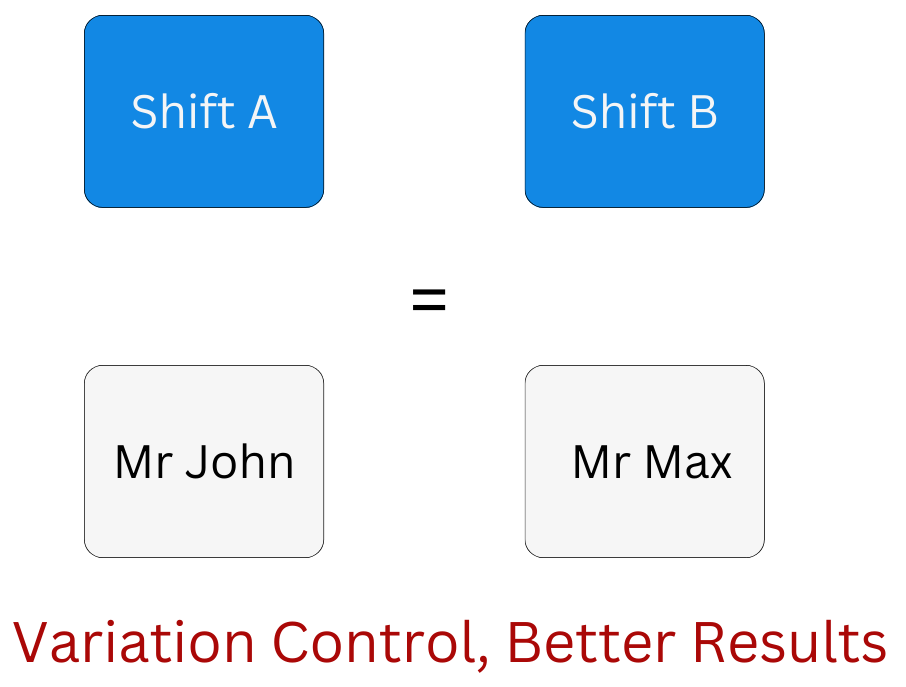

For any production plant, whether you are implementing a Lean Framework or not, a good Standard Work Procedure is a critical aspect of keeping the production running smoothly while minimizing manufacturing errors. When the workforce has a strong document or a video to follow step by step, it removes the variability of how Mr John is doing the job vs how Mr Max is doing the job. You get the same result every time in shift A vs Shift B. The workers are no more making their own decisions, but rather following what your company wants them to follow. This makes it easy to train new people in a high attrition environment. It also makes it easy to train Flex workers. Standard Work forms a Stability base for your production system.

Continuous Improvement - A Forever Aspect of Standard Work

No one knows the job station and the process better than the regular workers who work hard for 8 hours a shift continuously following the steps. Continuous improvement comes from them in most cases, with of course there are many inputs from the management as well. In a lean system, a good standard work is the one that is continuously evolving to a point where things can be done at a better rate and higher quality with least amount of material used. Allow your workers to sketch, update and provide suggestions on your standard work documents, even if they do it on a printed copy and scribble on it. The authorized workers or supervisors can then officially put this in Standard Work Pro and request approvals. This is a great way to improve consistently.

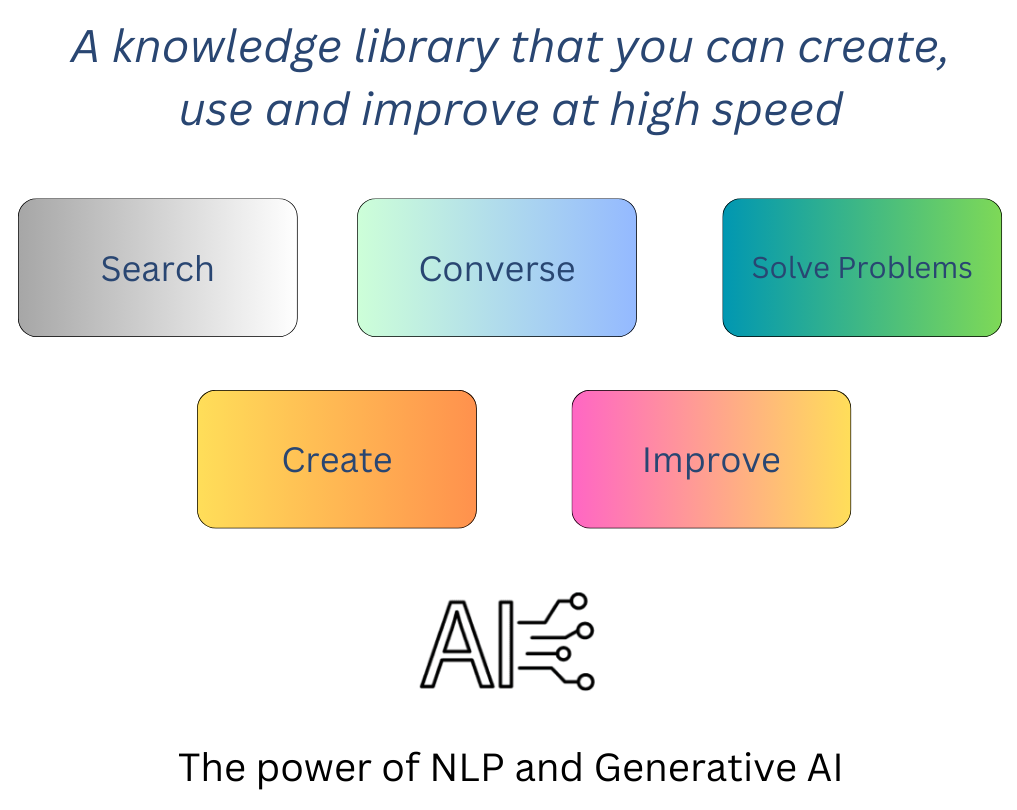

Artificial Intelligence is Optional

Our lean manufacturing software is at the forefront of AI integration, leveraging advanced technologies such as Large Language Models (LLMs) and Natural Language Processing (NLP) to transform how data is interacted with and analyzed on the shop floor. With optional AI capabilities, users can input data and soon engage in natural language conversations with our software. This AI-driven interface supports real-time querying and deep analysis, providing tailored insights through an intuitive, conversational user experience.

Our Software has standard work tools for lean manufacturing teams that helps in capturing and analyzing experience based knowledge from retiring employees, preserving essential insights and techniques. This structured knowledge is then made accessible to new staff, ensuring continuity and maintaining operational excellence as workforce demographics evolve. Choose our AI-enhanced manufacturing software for a safe, reliable, and insightful addition to your operational toolkit, ensuring that your shop floor remains innovative and competitive.

Pricing

Standard

Get a quote

Standard plan includes an advanced web software for your company.

Get a demoFeatures:

- Web application secured access

- Create in multiple formats

- Annotation Tools

- Manage Versions

- Print pdf

- Videos

- Approval Flow

- Reports

- Email Notifications and Alerts

- Role based access control

- High Security Protocols

AI (Artificial Intelligence)

Get a quote

Standard features plus Artificial Intelligence large language model integrated for insights and analysis.

Get a demoFeatures:

- All Standard Features included.

- Data synthesis and analysis with AI.

- Chat with AI and ask any questions regarding the data, comments or any information you have saved in Standard Work Pro for your plant.

- Build a knowledge library, generate content, solve problems and improve constantly.

Customized / Enterprise

Get a quote

Customized version as per your needs and specific plant use case. Enterprise deployment as per your requirements.

Get a demoFeatures:

- Customized Features.

- Customized deployment - your on premise server or your preferred company cloud, or a hybrid model.

- We work with you to understand your objectives, design and develop the software as per your needs.

- Talk to us about enterprise solution, for multiple plants / locations / changes in user management or any other requirements.

Choose the Deployment Options based on your Company Policies

ORCA LEAN Standard AWS Deployment

Deploy in your Company's On Premise Server

Deployment in your Company's Cloud

We understand and respect the fact that every plant has different challenges, organizational structure and culture. We will work with you to understand your requirements and customize our smart factory software solutions to best fit your needs. It is our goal to help you in your improvement initiatives for successful results.

Software Solutions for Manufacturing Excellence

Company

Social

Our Contact Info:

Email: contact@orcalean.com

Phone Number: 248 938 0375

Our Offices