20 Best Continuous Improvement Tools & Methods

June 6, 2025

Continuous improvement is more than a buzzword—it's the backbone of sustainable operational excellence. In manufacturing environments where quality, speed, and cost-effectiveness matter, choosing the right tools can make or break your improvement efforts. Whether you're a plant manager, CI leader, or process engineer, these 20 proven methods help eliminate waste, reduce variation, and empower your teams to solve problems better and faster.

Let’s dive into the most effective tools used in Lean, Six Sigma, and other CI frameworks.

Digital Revolution in Manufacturing Excellence

Forward-thinking manufacturers nowadays are adopting a digital-first strategy that's transforming the entire manufacturing model.

Manufacturing dashboards and next-generation KPI dashboards fill the gap by transforming raw data into crystal clear action-driving facts today. These aren't fancy-looking screens,they're your hub of operation excellence.

The alchemy truly occurs when problem-solving software is brought together with KPI dashboards, an area where teams can monitor defects in manufacturing with precision surgery.

This blended approach not only reduces defects in manufacturing but avoids them from even occurring in the first place.

20 Most Common Continuous Improvement Tools & Techniques

1. Kaizen

Continuous incremental improvements of entire organizations and not departments. This philosophy is not results-oriented, instituting lasting change with employee involvement and systematic problem-solving techniques. Events of Kaizen bring multi-functional teams to work and focus on a specific suggestion together.

- Creates a company-wide culture of improvement

- Eliminates waste in increments

- Increases employee participation and ownership

2. Plan-Do-Check-Act (PDCA)

Systematic four-step hypothesis testing process and implementation of improvements. This systematic format allows companies to solve problems in a systematic manner, providing sustainable improvements when the right planning and implementation are done.

- Provides systematic problem-solving structure

- Guarantees implementation of sustainability improvement

- Simplifies risk with systematic testing

Integrates with Solvonext to digitize each PDCA phase—offering real-time collaboration, automated data capture, and KPI dashboards that guide teams from planning through validation for faster, more sustainable results.

3. Lean Manufacturing

Gets rid of wastefulness while producing maximum value through the systematic elimination of non-value-added activities. This approach simplifies operations by emphasizing the customer value, producing efficient flows that minimize manufacturing costs.

- Gets rid of eight forms of wastefulness

- Improves operating performance

- Reduces production cost significantly

4. Six Sigma

Applies statistical techniques of minimizing the process variation and eliminating defects to near zero levels. A data-driven methodology utilizing DMAIC approach along with statistical techniques to provide breakthrough improvement in quality.

- Minimizes defects to 3.4 per million opportunities

- Offers powerful statistical problem-solving techniques

- Results in quantifiable financial performance

Are you confused between DMAIC and Six Sigma? And want to explore when to choose DMAIC and when to choose Six Sigma, then check our premium and well-explained presentation for FREE.

5. 5S Methodology

Creates efficient and clean working spaces through Sort, Set in Order, Shine, Standardize, and Sustain behaviors. This basic tool establishes visual control systems for safer and more efficient working conditions. Sort removes unnecessary work items. Set in Order creates specific slots to reduce search time. Shine ensures cleanliness while Standardize maintains these 3S and sustain improves it.

- Creates efficient working spaces

- Improves workplace safety and quality

- Establishes foundation for other improvements

Want to ensure your shop floor workers embrace continuous improvement behaviors on a consistent basis?

Consider using Orcalean’s manufacturing software to track defects that streamline workflow management and can be easily integrated with your quality management systems.

6. Total Quality Management (TQM)

Bridges quality principles across entire organizations, with a focus on continuous improvement for customer satisfaction. The integrated approach ensures quality becomes part of organizational culture and decision-making. It represents the quality embedded in organisation, culture, implementations and decisions.

- Integrates quality across the organization

- Prioritizes customer satisfaction

- Develops quality-oriented culture

7. Value Stream Mapping

Maps entire processes from the customer to the supplier, marking value-added and non-value-added steps. This potent tool exposes hidden waste, bottlenecks, and opportunity areas in processes. It helps in building priorities in the improvement slot.

- Identifies waste and bottlenecks unmistakably

- Guides focused improvement action

8. Root Cause Analysis

Identifies the underlying reasons for problems systematically instead of reacting to symptoms. This method avoids the recurrence of problems by rooting out the root causes using systematic questioning. It addresses fundamental issues through investigation between the teams.

- Avoids recurrence of problems

- Addresses root causes methodically

- Enhances long-term process stability

Solvonext enhances root cause analysis in manufacturing by digitizing every step—from data collection to corrective action. With built-in tools like the 5 Whys, Fishbone Diagram, and Pareto Charts, Solvonext ensures a standardized, traceable, and collaborative approach across shifts and teams. It helps manufacturers solve problems faster, reduce defect recurrence, and improve process reliability using a structured, digital-first RCA framework.

9. Statistical Process Control (SPC)

Tracks process performance statistically to catch variations prior to defect creation. This early warning measure stabilizes the process ahead of time. Its root lies in predictive capability and monitoring them gives immediate action response.

- Offers early warning of process variation

- Experiences consistent process performance

- Minimizes defective output to a great degree

10. Kanban

Graphs workflow work-in-progress for maximum throughput and minimum lead times. This pull system maximizes material flow with minimal overproduction. It includes the acceptance of a change after finding an existing process and encouraging leadership in the current responsibilities.

- Optimizes throughput and workflow

- Decreases lead times and inventory

- Enhances visibility of the process by far

11. A3 Problem Solving

Applies single-page reports to organize problem-solving thinking and communication. The graphical tool or problem solving software optimizes analysis through open documentation of problem-solving work. It is a visual tool that ensures proper analysis through comprehensive but clear documentation.

- Organizes systematic problem-solving processes

- Enhances documentation and communication

- Ensures thorough root cause analysis

12. DMAIC

Offers a five-step framework (Define, Measure, Analyze, Improve, Control) for solving complex problems. Formal procedure ensures rigorous analysis and permanent fixes. Firstly, define scopes and objectives then measure performances, analyse statistical data, implement solutions for it and in last, control and monitor them.

- Offers structured problem-solving framework

- Maintains complex improvement projects efficiently

- Ensures implementation of permanent solutions

13. Poka-Yoke

Applies error-proofing techniques that avoid making mistakes or detect them at early stages. The preventive method eliminates root causes of human error and improves the process reliability. It eliminates human errors and any error possibilities through its design and sensors.

- Avoids errors at source

- Greatly enhances process reliability

- Lessens inspection and rework expense

14. 5 Whys

Repeat "why" repeatedly to get down to the true root causes of problems. This simple powerful tool exposes root causes that are not always visibly obvious. The documentation involved in this captures and questions the root causes and provides a roadmap to avoid and find similar defects in future.

- Identifies real root causes promptly

- Easy technique with little training

- Avoids superficial problem-solving

15. Gemba Walking

Defines walking to actual workplaces to see processes in action and look for opportunities for improvement. The management technique ties leadership and frontline operations together. It improves the relation between workers and management and helps to address every minor issue.

- Links the management with the actual work

- Identifies opportunities for improvement on the spot

- Generates continuous improvement culture

Qualitygram supports effective Gemba Walks by providing a visual, real-time platform to capture observations, highlight issues, and assign follow-up actions directly from the shop floor. With photo annotations, workflow tracking, and audit-ready records, Qualitygram ensures that no improvement opportunity is lost—helping manufacturers build a culture of continuous improvement and proactive quality management.

16. Fishbone Diagram

Systematically classifies potential causes of problems through visual brainstorming methods. Systematic classification guarantees complete cause analysis but with simplicity of team brainstorming. It requires a diverse team and participation in finding the potential causes.

- Systematically classifies cause of problems

- Eases team brainstorming sessions

- Guarantees complete cause analysis

17. Control Charts

Tracks process performance over time with the help of statistical limits to detect changes. These tools differentiate between common and special cause variations. Different control charts are used for various types of data characteristics and help in interpreting data and signals.

- Tracks process performance continuously

- Differentiates types of variations clearly

- Recommends correct improvement actions

18. Failure Mode Analysis

Identifies potential failure points and their effect before failure. The proactive method decreases risk and enhances process reliability. Through identification, it reduces the chances of risk and makes improvement guides and sets priorities from manufacturing and design to service issues.

- Checks possible failures

- Decreases risk and enhances reliability

- Prevents expensive problem occurrence

19. Benchmarking

Compares performance with industry best available practices in an effort to identify areas for improvement. Outside consideration shows areas of performance weaknesses while offering roadmaps. Implementation of the analysis can bring out the capability in the organization culture and evolve from the current state.

- Compares performance with best practices

- Clearly shows areas of performance weaknesses

- Offers roadmaps for improvement

20. Standardized Work

Creates stable, repeatable processes that are foundations for continuous improvement. The process enables process stability with improvement baselines. Without this, suggestions and efforts lack sources and points to sustain gains. Regularity builds compliance and documentation currency.

- Creates stable process execution

- Provides improvement baseline

- Promotes sustainable process performance

Ready to track defects in manufacturing in a systematic way?

Take into account adopting KPI dashboard for manufacturing into your current quality management systems. These end-to-end platforms enable teams to decrease defects in manufacturing.

Shift your strategy to predictive from reactive.

What are the Advantages of Continuous Improvement Tools?

These potent methods create long-lasting change in your business and minimize defects in manufacturing.

- Lower Operation Cost - Eccentric software and computer programs for escalation of manufacturing make it easier to spot waste and inefficiencies consuming resources. Using quality management systems with integrated KPI dashboards, organizations generally achieve 15-30% savings on operation costs.

- Improved Product Quality - Problem-solving software allows teams to monitor and reduce defects in manufacturing, resulting in qualitative breakthroughs in quality.

- Enhanced Customer Satisfaction - A customer complaint is minimized as you reduce the defects in manufacturing by tracking the defects through digital software.

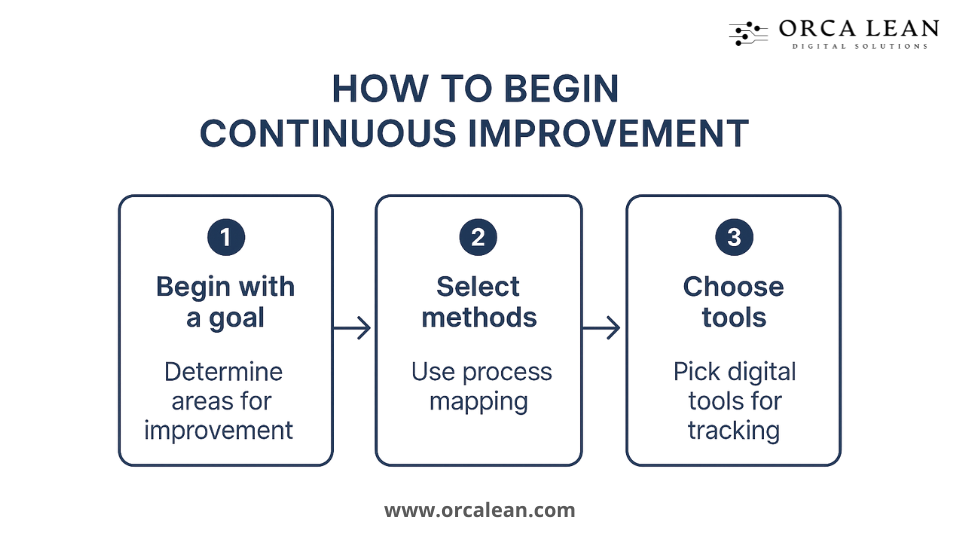

How to Begin Continuous Improvement?

What are Key Success Factors for Implementing Continuous Improvement?

Continuous improvement success is not solely a matter of choosing the correct tools - it's about creating a culture where improvement is an integral part of your organizational DNA.

1. Leadership Support and Commitment

If the management works actively to spread the quality management systems and invests in defect monitoring software, teams believe they can initiate a change. A genuine commitment can be achieved by dedicated initiatives and resources.

Toyota does gemba walks and spends time on the factory regularly to observe improvements.

2. Employee Training and Engagement

Make sure your workers are trained to operate SQDC dashboards, KPI dashboards, and other software tools to monitor defects. Training programs with technical skills and solution-oriented methodologies can empower workers.

General Electric trains more than 90,000 in their Six Sigma program to address quality issues.

3. Data-Driven Decision Making

Establish sound measurement systems through manufacturing dashboards that deliver real-time information. Robust data collection operations can ensure accuracy and data accessibility.

Amazon uses live dashboards for operations to identify problems and perform actions with weekly reports.

Conclusion

Continuous improvement is no longer optional—it’s the foundation of competitive advantage in modern manufacturing. From minimizing defects to driving team engagement, the right tools make all the difference. But to truly maximize these methods, you need a system that unifies them.

That’s where Solvonext comes in. It brings your entire CI strategy to life—digitizing PDCA cycles, streamlining root cause analysis, and powering real-time KPI dashboards. Whether you're reducing scrap, preventing rework, or accelerating problem resolution, Solvonext transforms your factory into a high-performance, data-driven environment. If you're serious about continuous improvement, it’s time to upgrade from paper-based tracking and disconnected systems.

Start your digital transformation with Solvonext and make improvement the default, not the exception.

Software Solutions for Manufacturing Excellence

Company

Social

Our Contact Info:

Email: contact@orcalean.com

Phone Number: 248 938 0375

Our Offices