How Toyota Builds Confidence in Its Blue-Collar Workforce?

March 6, 2025

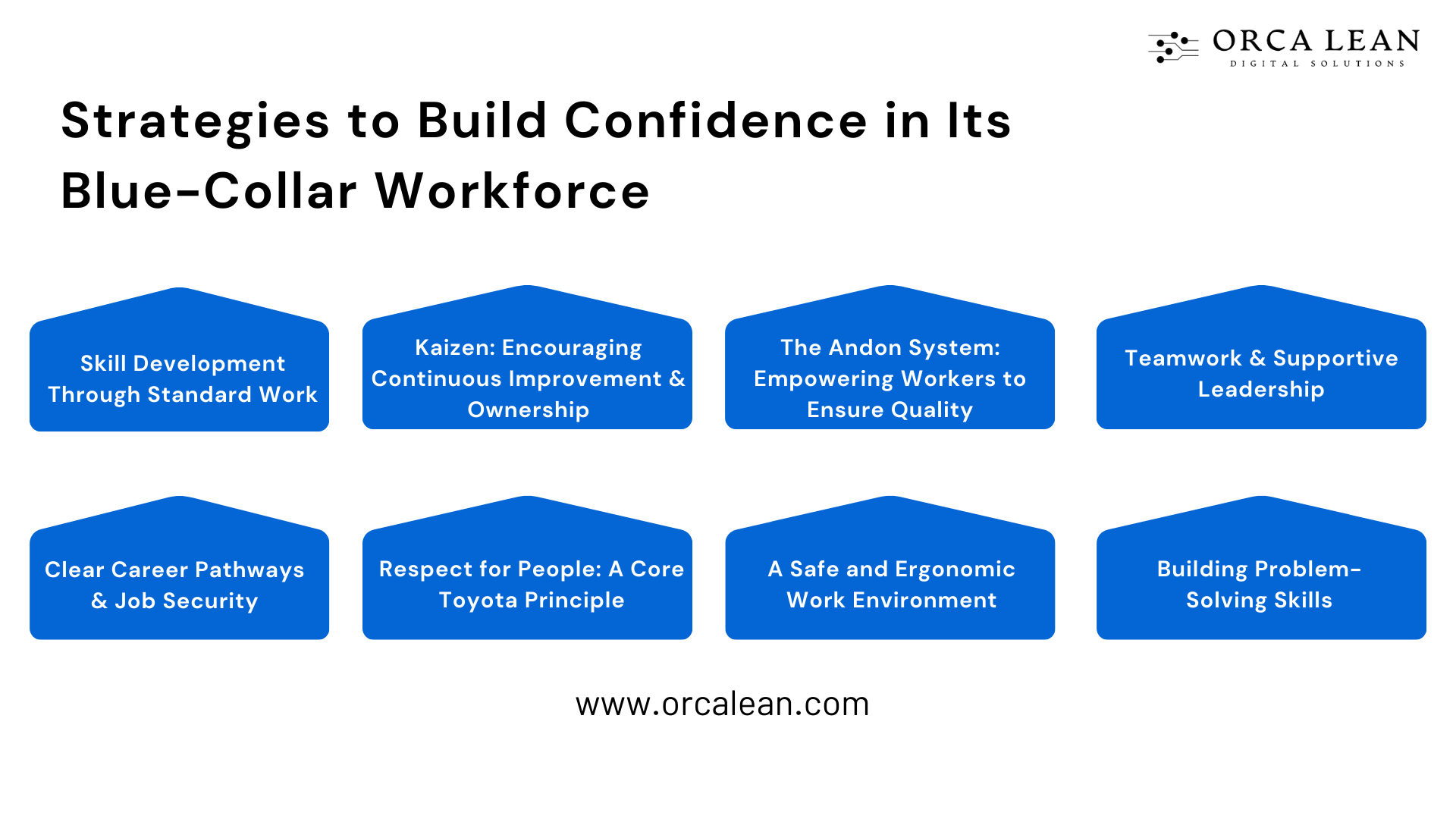

In the world of manufacturing, workforce confidence plays a crucial role in productivity, quality, and overall operational success. Toyota, a leader in lean manufacturing and continuous improvement, has developed a structured approach to building confidence in its blue-collar workforce. Their methods go beyond just training—they empower employees, involve them in decision-making, and provide clear career pathways.

This blog explores the key strategies Toyota employs to ensure its factory workers are skilled, motivated, and confident in their roles.

1. Skill Development Through Standard Work

At the heart of Toyota’s approach to workforce confidence is Standard Work—a detailed and structured way of performing tasks that ensures consistency and efficiency. This methodology allows workers to:

- Follow clear, documented processes to create standard work for minimizng variability in tasks.

- Gain hands-on training to master their roles and become proficient.

- Understand expectations, reducing uncertainty and boosting self-assurance.

Toyota’s Training Within Industry (TWI) Program further strengthens skill development. This program focuses on:

- Job Instruction (JI): Teaching employees how to do their job correctly and safely.

- Job Methods (JM): Encouraging workers to improve their own processes.

- Job Relations (JR): Building positive relationships and confidence in the workplace.

By setting clear work standards and providing structured training, Toyota ensures that workers feel competent and confident in their roles.

2. Kaizen: Encouraging Continuous Improvement and Ownership

Confidence grows when employees feel that their input matters. Toyota fosters this by embedding Kaizen, or continuous improvement, into everyday operations. Workers are encouraged to:

- Identify inefficiencies in their tasks and suggest improvements.

- Participate in Kaizen events, where teams work together to enhance processes.

- Take ownership of their workstations, ensuring a sense of responsibility and pride.

This approach not only improves processes but also reinforces the idea that every worker is a valuable contributor to Toyota’s success. When employees see their ideas implemented, they gain confidence in their problem-solving abilities.

3. The Andon System: Empowering Workers to Ensure Quality

One of Toyota’s most famous confidence-building strategies is the Andon Cord System. Unlike traditional manufacturing settings where workers fear stopping the production line, Toyota gives employees the authority to halt operations if they notice a defect or issue.

How does this build confidence?

- Workers feel trusted to make critical quality decisions.

- They are actively involved in problem-solving, rather than just following orders.

- They develop a sense of responsibility for the final product’s quality.

This practice shifts the mindset from simply "doing a job" to being a key player in maintaining Toyota’s high-quality standards.

4. Teamwork and Supportive Leadership

Toyota’s workplace culture emphasizes teamwork, which helps workers feel supported and encouraged. Some of the key ways Toyota fosters teamwork include:

- Daily team huddles where workers discuss challenges and achievements.

- Team-based problem-solving, ensuring workers collaborate rather than compete.

- Mentorship programs, where experienced employees guide new hires.

Supervisors at Toyota also play a critical role in building confidence. Instead of acting as authoritarian figures, they work alongside employees, listen to concerns, and provide regular feedback. This creates an environment where workers feel heard and respected.

5. Clear Career Pathways and Job Security

Nothing kills confidence faster than job uncertainty. Toyota tackles this by providing:

- Long-term employment opportunities, reducing the fear of layoffs.

- Job rotation programs, allowing workers to gain new skills and explore different roles.

- Clear career progression, showing workers a path from entry-level roles to leadership positions.

By offering stability and growth opportunities, Toyota ensures that workers see a future within the company, which strengthens their self-esteem and commitment.

6. Respect for People: A Core Toyota Principle

Toyota’s corporate philosophy, The Toyota Way, includes two core pillars: Continuous Improvement and Respect for People. The latter plays a major role in boosting employee confidence.

- Workers are treated as partners, not just laborers.

- Toyota ensures that employees have a voice in decision-making.

- Recognition and rewards are regularly given for contributions and innovations.

This culture of respect helps workers feel valued, which directly impacts their confidence and engagement.

7. A Safe and Ergonomic Work Environment

Workplace safety and comfort also play a significant role in confidence. Toyota invests in:

- Ergonomically designed workstations, reducing strain and fatigue.

- Safety training programs, ensuring workers feel secure.

- Proactive risk management, encouraging employees to report hazards.

When workers know they are in a safe environment and that their well-being is a priority, they feel more confident in their daily tasks.

8. Building Problem-Solving Skills

Toyota doesn’t just train workers to follow instructions; it trains them to think critically and solve problems. Employees are taught Toyota’s problem-solving methodology, including:

- A3 Thinking – A structured way to approach and solve problems.

- Root Cause Analysis (5 Whys, Fishbone Diagrams) – Encouraging deeper thinking rather than surface-level fixes.

- PDCA (Plan-Do-Check-Act) – Teaching workers how to test and refine solutions.

This level of intellectual engagement gives workers confidence in their ability to handle challenges rather than rely on supervisors for every issue.

Conclusion

Toyota’s success is not just about lean processes or automation—it is deeply rooted in how it builds the confidence of its blue-collar workforce. By investing in skills, promoting continuous improvement, empowering workers, ensuring job security, fostering teamwork, and prioritizing respect, Toyota has created an environment where workers feel valued, capable, and engaged.

For manufacturers looking to improve workforce morale and efficiency, Toyota’s approach provides a proven blueprint for developing a confident, motivated, and high-performing workforce.

One key enabler of this transformation is structured, clear work instructions. Standard Work Pro helps manufacturers implement standardized processes that empower workers, reduce variability, and enhance confidence on the shop floor.

Software Solutions for Manufacturing Excellence

Company

Social

Our Contact Info:

Email: contact@orcalean.com

Phone Number: 248 938 0375

Our Offices