The Digital Toolbox: Must-Have Online Calculators for Lean Manufacturing

March 17, 2025

Lean manufacturing is all about efficiency, waste reduction, and continuous improvement. To achieve these goals, manufacturers need real-time data to make quick and informed decisions. Digital calculators play a crucial role in this process.

With the right online tools, companies can streamline operations, reduce errors, and improve key performance indicators (KPIs). Whether it's optimizing production schedules, improving equipment efficiency, or calculating cost savings, these calculators are essential for lean success. In this blog, we explore the must-have digital tools every lean practitioner should use.

The Role of Digital Calculators in Lean Manufacturing

Digital calculators are online tools designed to help manufacturers quickly perform key calculations related to production efficiency, cycle time, takt time, and cost savings. Unlike manual methods or spreadsheets, these tools provide instant, accurate, and actionable insights.

Why Do Digital Calculators Matter in Lean Manufacturing?

- Instant Accuracy – Manual calculations can lead to errors. Digital calculators eliminate guesswork and miscalculations.

- Real-Time Decision Making – With instant results, manufacturers can adjust production processes on the spot.

- Eliminating Waste – By optimizing key metrics, manufacturers can reduce downtime, inefficiencies, and unnecessary costs.

- Better Forecasting – Accurate calculations help companies plan production schedules and resource allocation effectively.

- Standardization – Using the same tools across teams ensures consistency in calculations and decision-making.

Traditional spreadsheet-based calculations can be tedious and error-prone. Lean manufacturing requires accurate and fast calculations to improve OEE, takt time, cycle time, and cost savings. Digital calculators provide instant insights, allowing manufacturers to adjust processes in real time. By leveraging these tools, companies can enhance performance, minimize downtime, and achieve continuous improvement.

To learn and explore more about Paper vs Digital Data Acquisition in Manufacturing, check out our presentation that explores how digital systems streamline data collection, reduce human error, and provide real-time insights, leading to better decision-making and efficiency.

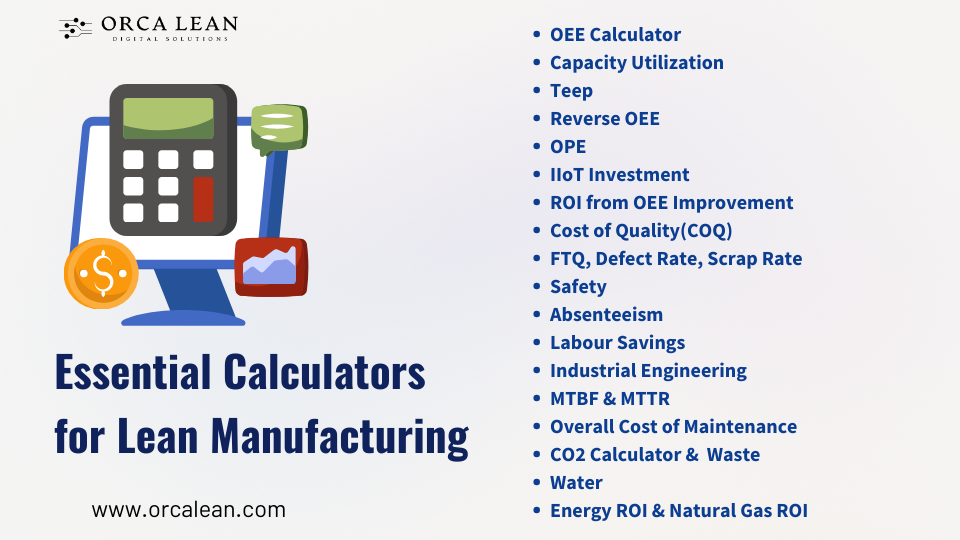

Essential Online Calculators for Lean Manufacturing

Digital tools simplify lean manufacturing by providing fast, error-free calculations. Below are four must-have calculators that drive efficiency and profitability.

Overall Equipment Effectiveness (OEE) Calculator

OEE measures manufacturing productivity by evaluating availability, performance, and quality. It helps identify inefficiencies and optimize equipment utilization.

How an OEE Calculator Helps

- Instantly calculates OEE based on real-time data.

- Identifies downtime causes and performance gaps.

- Helps manufacturers improve machine utilization.

Example: Where an OEE Calculator is a Must-Have

A food processing plant struggles with frequent machine breakdowns, reducing overall efficiency. By using an OEE calculator, they track equipment availability and performance issues. The data helps them schedule preventive maintenance, reducing downtime by 20% and improving production output.

Takt Time Calculator

Takt time ensures production meets customer demand without overproduction or delays. It helps balance workload and optimize production flow.

How a Takt Time Calculator Helps

- Aligns production speed with customer demand.

- Prevents bottlenecks and eliminates idle time.

- Enhances workflow efficiency.

Example: Where a Takt Time Calculator is a Must-Have

An electronics manufacturer struggles with inconsistent production rates, leading to backorders and excess inventory. Using a takt time calculator, they align production with real demand, reducing stock accumulation and improving on-time delivery by 25%.

Cycle Time & Lead Time Calculator

Cycle time measures the time to complete one product, while lead time covers the total time from order to delivery. Both are critical for lean efficiency.

How a Cycle Time & Lead Time Calculator Helps

- Helps identify process bottlenecks.

- Improves production scheduling and delivery timelines.

- Reduces delays and enhances process efficiency.

Example: Where a Cycle Time & Lead Time Calculator is a Must-Have

A textile company faces long order fulfillment times. By using a cycle and lead time calculator, they identify slow stitching processes as the bottleneck. After optimizing workflow, they cut order fulfillment time by 35%, improving customer satisfaction.

Explore the difference between Takt Time and Cycle Time in our detailed blog.

Cost Savings & ROI Calculator

Cost savings and ROI are critical for assessing the impact of lean initiatives. Manufacturers need data to justify process improvements.

How a Cost Savings & ROI Calculator Helps

- Provides financial justification for lean projects.

- Identifies areas where cost reductions can be made.

- Helps track ROI over time.

Example: Where a Cost Savings & ROI Calculator is a Must-Have

A packaging company invests in automation to reduce material waste. Using a cost savings calculator, they track savings from reduced defects and labor costs. The tool reveals a 30% decrease in material waste, proving automation’s profitability.

Maximizing Your Results with Oraclean’s Digital Tools

Oraclean is committed to equipping manufacturers with powerful digital tools for manufacturing that simplify calculations, eliminate errors, and support continuous improvement. In today’s fast-paced production environment, manual calculations can slow down decision-making and introduce inefficiencies. Our suite of free online calculators ensures that lean professionals have instant access to accurate data, helping them drive better outcomes.

From optimizing production efficiency to tracking key performance indicators, our tools cater to various roles, including Quality Managers, HR Managers, EHS Managers, Plant Managers, Engineers, and Maintenance Managers. Whether it's improving workflow, ensuring compliance, or calculating resource efficiency, Oraclean’s digital toolbox provides essential support for professionals across all areas of manufacturing.

By leveraging these calculators, manufacturers can reduce waste, enhance productivity, and maintain operational excellence without relying on complex spreadsheets.

Conclusion: Future-Proof Your Lean Strategy with Digital Tools

Manufacturers can no longer rely on manual calculations. Digital tools are essential for optimizing performance, reducing waste, and driving profitability.

By using the right calculators, companies can make data-driven decisions, eliminate inefficiencies, and improve productivity. Oraclean’s suite of free digital tools helps manufacturers achieve lean success effortlessly.

Don’t let inefficiencies slow you down—start using Oraclean’s manufacturing digital calculators today! Explore our free tools and take your lean strategy to the next level.

Software Solutions for Manufacturing Excellence

Company

Social

Our Contact Info:

Email: contact@orcalean.com

Phone Number: 248 938 0375

Our Offices