Common Mistakes When Converting Paper SOPs to Digital

September 23, 2025

For decades, U.S. factories have depended on paper-based Standard Operating Procedures (SOPs) to guide their workforce. But today’s manufacturing reality—tight labor markets, complex compliance requirements, and the demand for real-time agility—has made paper SOPs a serious liability. That’s why more manufacturers are embracing digital SOP software for manufacturing.

The shift promises improved compliance, better operator training, and more consistent quality. Yet, many manufacturers stumble during the transition. Converting paper to digital SOPs isn’t as simple as scanning documents into a database. Done wrong, it can create confusion, noncompliance, and wasted investment. In this blog, we’ll highlight the most common mistakes U.S. manufacturers make when digitizing SOPs, and how you can avoid them.

Why Are Manufacturers Moving Away from Paper SOPs?

Paper SOPs often fall short in today’s environment. They get outdated quickly, revisions are hard to track, and frontline workers often rely on word-of-mouth instead of the most current procedure. This exposes factories to quality risks, audit failures, and in some industries, fines or recalls.

By contrast, standard work procedure tools for U.S. manufacturers offer several advantages:

- Real-time updates: Operators always see the latest instructions.

- Built-in compliance tracking: Digital trails satisfy ISO, FDA, or IATF auditors.

- Improved training: Visual workflows and step-by-step guides help new employees ramp up faster.

- Lean alignment: Digital SOPs fit into broader lean manufacturing digital SOP solutions, supporting continuous improvement.

For these reasons, many U.S. factories are actively replacing outdated binders with the best standard work procedure software for factories. But the transition is rarely seamless. Let’s explore the most common pitfalls.

One of the biggest conversion mistakes is overly complex workflows — too much detail, technical language, or steps not relevant to the operator. As highlighted in Why U.S. Operators Struggle With SOP Compliance—and How to Fix It Digitally, “Overly Complex, Paper-Based Procedures” are a root cause of SOP non-compliance. Simplifying steps, adding visuals, and ensuring instructions are easy to follow on the shop floor can drastically reduce error rates.

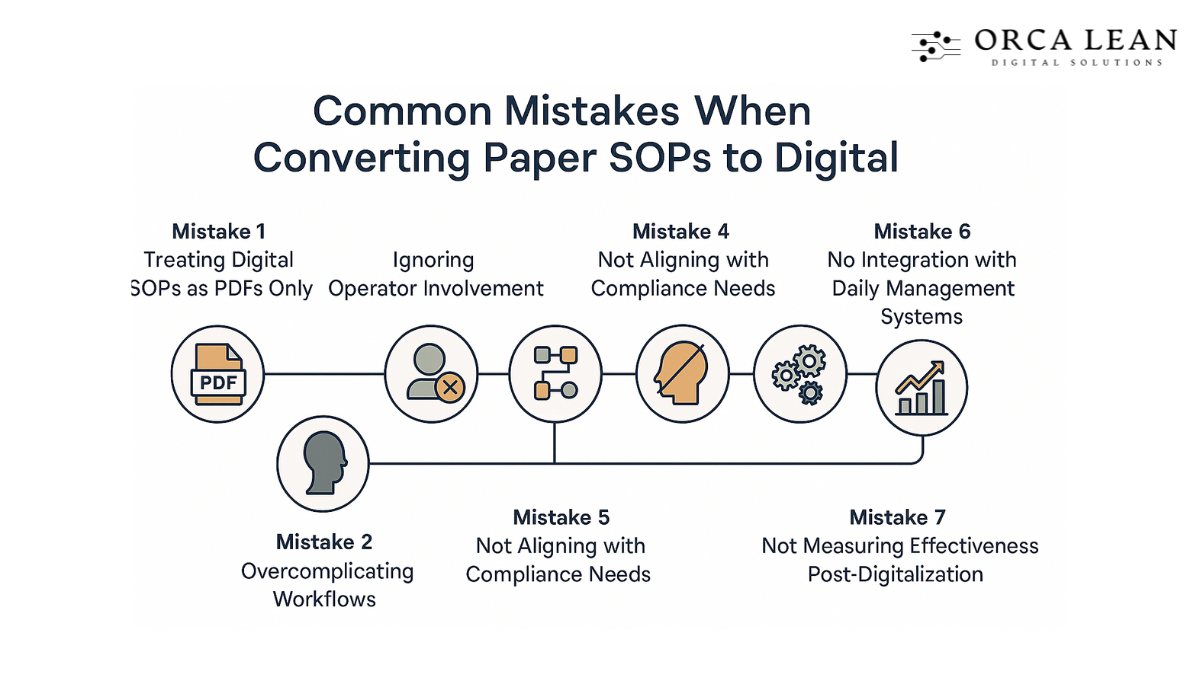

Common Mistakes in Converting SOPs to Digital

Mistake 1: Treating Digital SOPs as PDFs Only

Many manufacturers think they’re “going digital” by scanning their SOP binders into PDFs. While this may reduce paper clutter, it doesn’t solve the real problems. Operators can’t search or interact with PDFs easily, and revision control remains clunky.

True digital SOPs should be workflow-driven and interactive—not static documents. A good alternative to paper SOPs in manufacturing means step-by-step tasks with embedded visuals, links to training modules, and version history that is instantly accessible.

Mistake 2: Ignoring Operator Involvement

Frontline operators are the ones who use SOPs daily. Yet in many digital rollouts, their input is overlooked. This creates resistance and low adoption, especially in U.S. factories where experienced workers often prefer “the old way.”

Engaging operators early—through workshops or pilot tests—ensures that digital SOPs reflect the real sequence of work, not just management’s idealized version. Without operator buy-in, digital SOP implementation challenges multiply.

Mistake 3: Overcomplicating Workflows

Another common mistake is overloading digital SOPs with unnecessary detail. Some managers see digital tools as an excuse to add long explanations, technical jargon, or excessive checklists. But complexity backfires.

Operators need clarity and speed. SOPs should provide enough detail to ensure consistency, but they must also mirror the actual work on the shop floor. Visuals, icons, and logical branching are far more effective than dense text blocks.

Mistake 4: Skipping Change Management

Digital SOP rollouts often fail because manufacturers underestimate the cultural shift required. Management may assume that installing software is enough, but without training and communication, compliance suffers.

In the U.S., where workforce turnover is high, neglecting change management is especially risky. Factories must invest in training sessions, coaching, and clear communication about “why” the shift is happening. Without this, manufacturing SOP digitalization mistakes escalate quickly.

Mistake 5: Not Aligning with Compliance Needs

For manufacturers in sectors like automotive, aerospace, or medical devices, compliance is non-negotiable. Digital SOPs must create audit-ready trails that prove operators followed the approved version. Yet many systems fail to deliver this, leaving plants exposed during ISO or FDA inspections.

Manufacturing compliance digital SOP features—such as time-stamped revisions, approval workflows, and sign-offs—must be built into your system. If your digital SOP software doesn’t support compliance, you’ve replaced one risk with another.

Mistake 6: No Integration with Daily Management Systems

Some factories implement digital SOPs as standalone systems. While this may work at first, it eventually leads to silos. For real value, SOPs should integrate with training, problem-solving, and KPI tracking systems.

For example, linking SOP usage to daily SQDC dashboards helps supervisors see whether deviations are causing quality or delivery issues. Integration makes SOPs a living part of your continuous improvement cycle, not just a digital archive.

Mistake 7: Not Measuring Effectiveness Post-Digitalization

Digitization isn’t the end goal—performance improvement is. Many manufacturers forget to measure whether digital SOPs actually reduce errors, training time, or downtime.

KPIs like First Time Quality (FTQ), defect rate, or training completion speed are critical for proving ROI. Without tracking these, it’s impossible to know if your investment in digital SOP software is paying off.

Best Practices to Avoid These Mistakes

To ensure a successful transition, U.S. manufacturers should follow these proven strategies:

- Start small, focus on high-risk processes: Pilot in areas like changeovers, CCP checks, or sanitation, where compliance is critical.

- Use purpose-built tools: Generic document systems don’t work well for operators. Choose the best standard work procedure software for factories that includes visual workflows, compliance tracking, and integration.

- Embed SOPs into daily routines: Link SOPs to training, audits, and problem-solving tools so they become part of everyday work.

- Prioritize usability: If operators can’t use it quickly and intuitively, adoption will fail.

- Ensure compliance-ready trails: Audit-readiness should be automatic, not manual.

By following these steps, factories can avoid the digital SOP implementation challenges that derail so many initiatives.

Conclusion

Digitizing SOPs is more than replacing paper—it’s about building a smarter, more resilient, and compliant factory. Done poorly, digitalization can create new headaches. Done right, it streamlines training, boosts compliance, and strengthens lean practices.

For U.S. manufacturers aiming to eliminate these manufacturing SOP digitalization mistakes, investing in a system designed for the shop floor is essential. Tools like Standard Work Pro provide the usability, compliance, and integration that factories need to succeed.

If your plant is ready to move beyond paper and embrace the best standard work procedure software for manufacturing, now is the time to act. Digital SOPs are no longer optional—they’re the foundation of operational excellence.

Software Solutions for Manufacturing Excellence

Company

Social

Our Contact Info:

Email: contact@orcalean.com

Phone Number: 248 938 0375

Our Offices