The Risk of Overloaded SOPs: When Too Much Text Leads to Errors

September 24, 2025

In manufacturing, Standard Operating Procedures (SOPs) are the foundation of consistency, safety, and quality. They guide operators step by step, reduce human error, and ensure compliance with industry standards. But what happens when SOPs become overloaded with too much text?

Instead of helping, these bloated documents slow operators down, confuse new hires, and often get ignored on the shop floor. For manufacturers aiming to stay competitive in a lean-driven, digital-first environment, overloaded SOPs are more than an inconvenience—they are a liability.

In this article, we’ll explore why SOPs get overloaded, the risks they create, and how modern digital SOP software can transform them into effective, visual tools that operators actually use.

Why Do SOPs Become Overloaded?

If you walk into a factory today and ask operators about SOPs, chances are you’ll hear the same frustrations: “They’re too long,” “They don’t match how we really work,” or “I can’t find the step I need.” These issues are not random—they stem from common mistakes in how SOPs are written and managed.

1. Compliance Pressure

In highly regulated industries—automotive, aerospace, food, or pharma—manufacturers fear missing details during audits. The response is over-documentation: entire SOPs stuffed with every possible scenario, no matter how rare.

2. Fear of Liability

Supervisors add “just in case” instructions. While well-intentioned, these additions eventually bury critical steps in unnecessary text.

3. Copy-Paste Updates

Instead of rewriting SOPs during revisions, teams often paste new information on top of old instructions. Over time, the document becomes a patchwork of disconnected sections.

4. Disconnected Authors

Engineers and managers who draft SOPs may not spend much time on the shop floor. Without operator input, SOPs reflect theory more than practice—resulting in procedures that look good in audits but fail in real-world use.

The outcome: SOPs that are accurate on paper but impractical in execution.

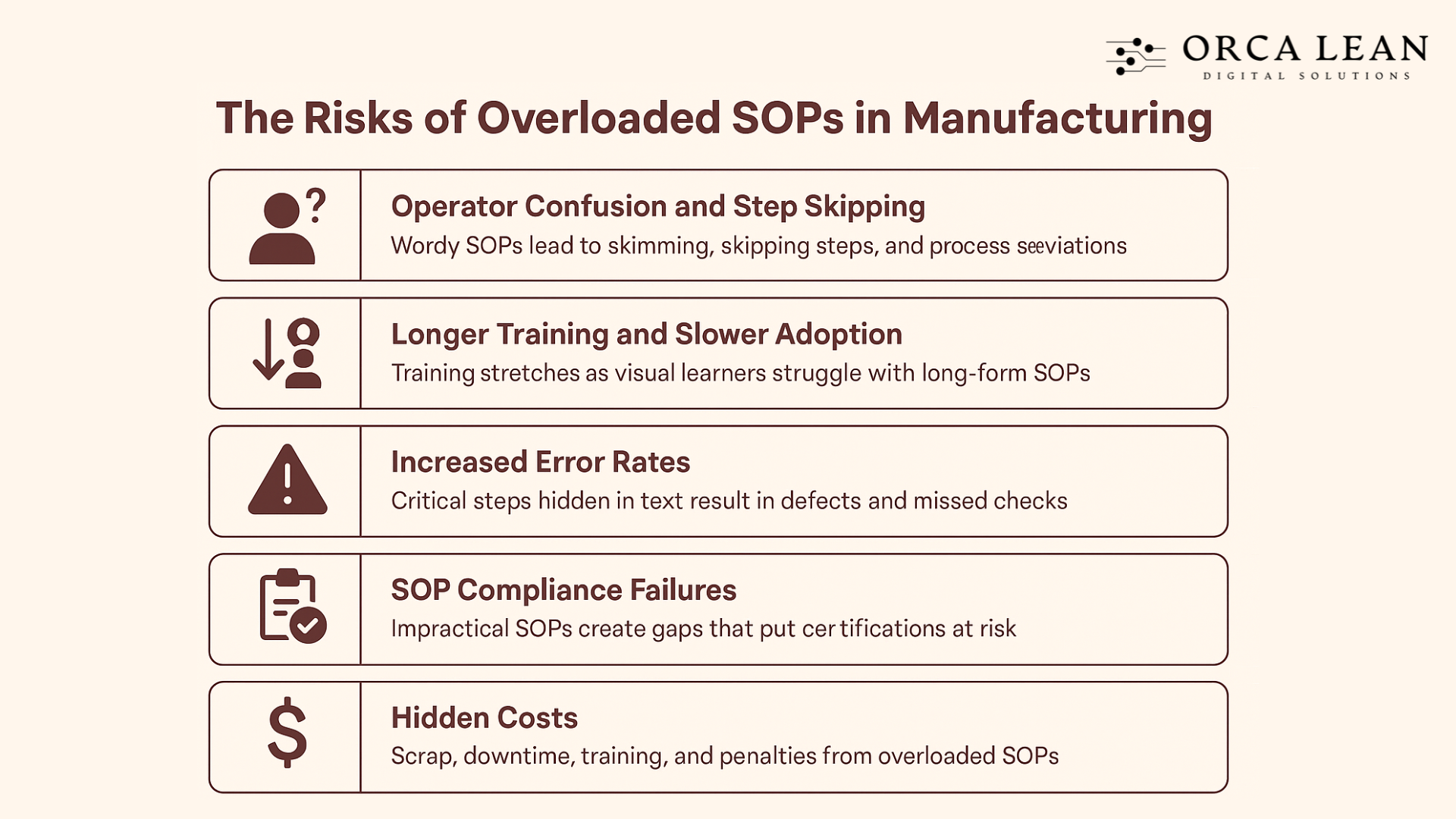

The Risks of Overloaded SOPs in Manufacturing

1. Operator Confusion and Step Skipping

When operators are under time pressure, a 10-page SOP filled with dense paragraphs is unlikely to be followed line by line. Instead, workers skim, skip, or rely on memory. This directly leads to process deviations, inconsistent output, and errors.

2. Longer Training and Slower Adoption

Training new hires is already a costly endeavor. When SOPs are wordy, onboarding stretches longer than necessary. Visual learners in particular struggle with long-form instructions, making adoption uneven across teams.

3. Increased Error Rates

Critical steps can be buried in blocks of text. Operators may overlook safety precautions or quality checks, leading to defects, downtime, or even workplace incidents.

4. SOP Compliance Failures

Auditors don’t just check for documentation—they look for proof that operators actually follow procedures. When SOPs are impractical, compliance gaps appear. This puts ISO, FDA, and IATF certifications at risk.

5. Operator Resistance

When procedures feel disconnected from reality, workers disengage. SOPs are seen as “bureaucratic paperwork” rather than helpful tools. This cultural resistance undermines lean manufacturing SOPs and continuous improvement projects.

6. Hidden Costs

- Scrap and rework due to skipped steps

- Increased downtime from operator errors

- Repeated training costs

- Compliance penalties from failed audits

In short: overloaded SOPs are not just a paperwork problem—they are a financial one.

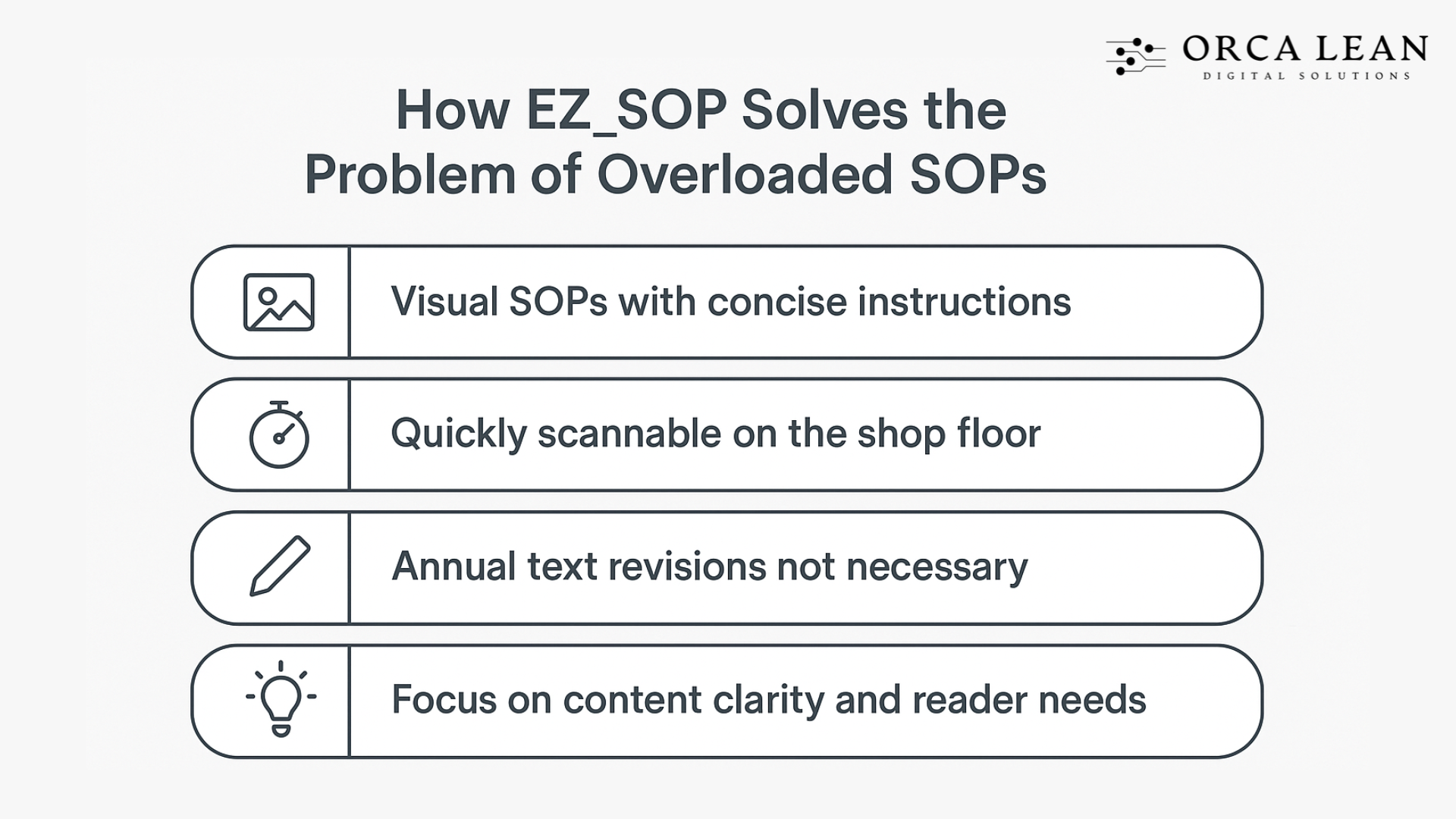

How EZ_SOP Solves the Problem of Overloaded SOPs?

Paper SOPs and static PDFs simply can’t keep up with the speed and complexity of modern manufacturing. They get buried in binders, go out of date quickly, and often overwhelm operators with walls of text. That’s where EZ_SOP comes in—built specifically to transform SOP management into a lean, visual, and operator-friendly system.

Here’s how EZ_SOP tackles the biggest challenges of overloaded SOPs:

1. Instant Access with Barcode and QR Integration

In a busy plant, every second counts. Hunting through folders, drives, or filing cabinets for the right SOP wastes valuable time. With EZ_SOP, operators can simply scan a barcode or QR code on the machine or workstation and instantly pull up the exact procedure they need.

- No delays, no mix-ups, no excuses for skipping steps.

- Supervisors gain confidence knowing that every worker is looking at the right document, at the right time.

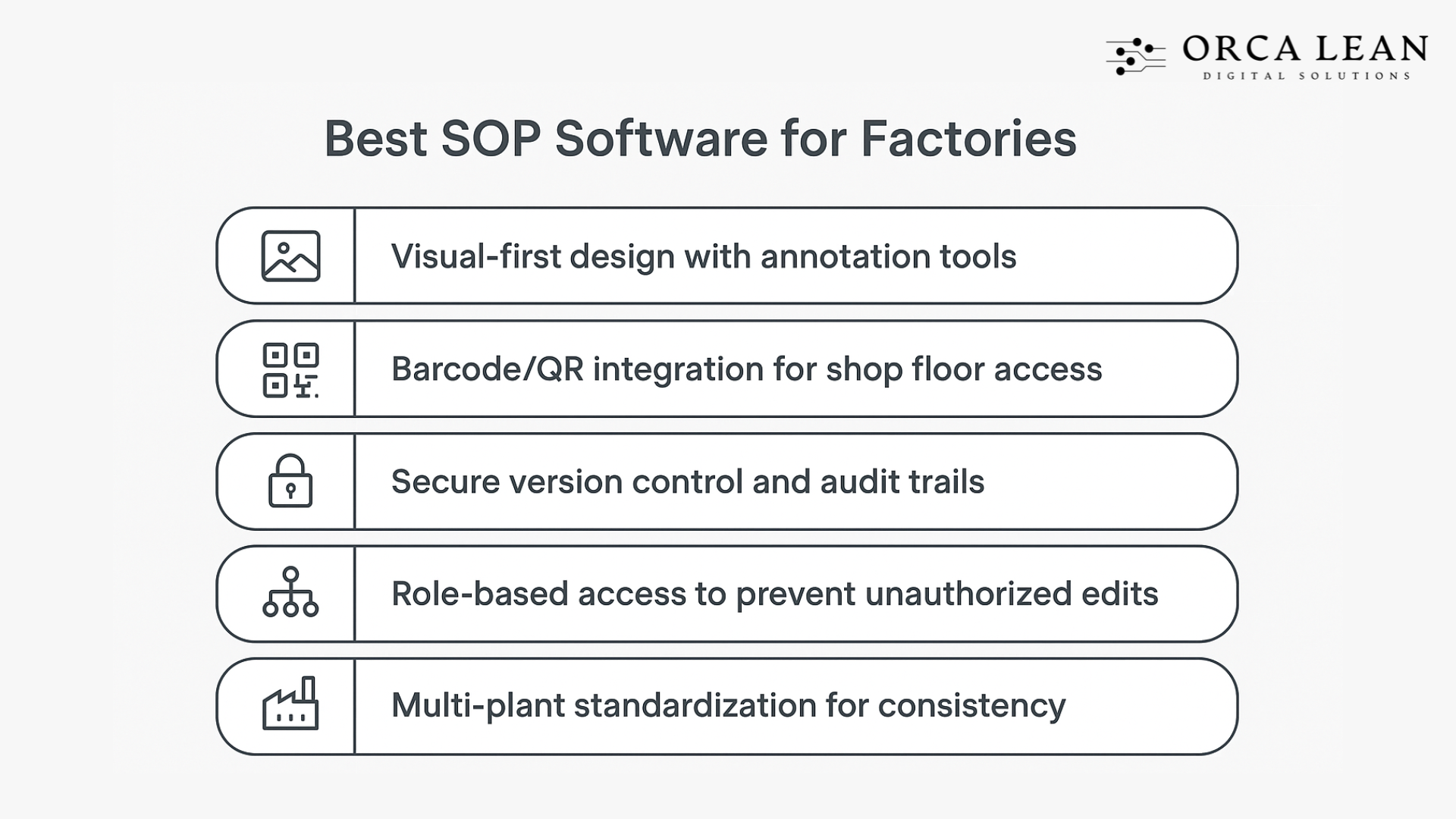

2. Visual-First Design: 80% Images, 20% Text

Traditional SOPs overwhelm operators with paragraphs of text. EZ_SOP flips the model. It’s designed around the principle of visual SOPs for operators—using annotated images, diagrams, and callouts that make instructions easy to follow.

- Operators don’t need to read through pages; they can see exactly what needs to be done.

- Complex processes are simplified, reducing errors and training time.

This image-first approach is why factories using EZ_SOP report faster onboarding and fewer mistakes.

3. Controlled Version Management and Audit Trails

One of the most dangerous problems in manufacturing is multiple versions of SOPs floating around. An operator may unknowingly follow an outdated procedure, leading to compliance failures or defects.

EZ_SOP eliminates this risk with robust version control:

- Every SOP gets a unique ID and barcode, ensuring operators only see the latest approved version.

- A full change history is recorded—who made updates, when, and why.

- During audits, you can demonstrate complete traceability and compliance.

This makes SOP compliance in manufacturing not just easier but bulletproof.

4. Role-Based Access and Security

In many plants, SOPs are updated by whoever has access to the file. This creates chaos and a lack of accountability. With EZ_SOP:

- Only authorized users can create, edit, or approve SOPs.

- Operators on the floor always see the correct, approved version.

- Managers can control access across departments or locations, ensuring consistency.

This governance reduces the risk of unauthorized edits and strengthens trust in SOPs across teams.

5. Deployment Flexibility: Cloud, On-Premise, or Hybrid

Every manufacturer has different IT policies and security needs. EZ_SOP adapts:

- Cloud deployment for scalability and ease of access.

- On-premise deployment for highly regulated industries or data-sensitive environments.

- Hybrid options for multi-plant enterprises that need both.

This flexibility means EZ_SOP can fit into any factory’s infrastructure without disruption.

6. Supports Lean Manufacturing SOPs and Continuous Improvement

SOPs shouldn’t just enforce consistency—they should also evolve as teams improve processes. EZ_SOP is designed with lean in mind:

- Easy to update after Kaizen events, audits, or improvement projects.

- Operators can provide feedback, creating a loop between the floor and management.

- Helps sustain continuous improvement by making updated standards available instantly.

With EZ_SOP, SOPs stop being static paperwork and become active tools for driving lean culture.

7. Multi-Plant Standardization

For manufacturers with multiple sites, standardizing SOPs is a major challenge. Different plants often tweak documents, creating inconsistency. EZ_SOP solves this by:

- Centralizing SOPs in one controlled platform.

- Rolling out approved updates across multiple plants at once.

- Ensuring every location follows the same standards while allowing site-specific customization when necessary.

This creates a stronger foundation for quality, safety, and efficiency across the enterprise.

Why Do Manufacturers Choose EZ_SOP?

Unlike generic document management systems, EZ_SOP is built for factories. It combines visual-first SOP design, secure version control, instant shop floor access, and lean-driven features into a single platform that operators actually use.

The result?

- Fewer errors on the floor.

- Faster training and onboarding.

- Stronger compliance during audits.

- Lower costs from reduced scrap and rework.

- Higher engagement from operators who finally see SOPs as tools, not burdens.

In short: EZ_SOP transforms SOPs from overstuffed documents into simple, visual, and compliant guides that minimize errors and strengthen your factory’s lean culture.

Conclusion

Overloaded SOPs are a silent threat to manufacturing excellence. What looks like “thorough documentation” often leads to confusion, skipped steps, and compliance failures. For U.S. factories competing in lean-driven markets, text-heavy SOPs aren’t just inefficient—they’re costly.

By applying manufacturing SOP best practices and avoiding common mistakes, manufacturers can create SOPs that truly support operators. More importantly, by adopting digital SOPs for manufacturing, companies can cut through complexity, improve compliance, and reduce errors.

Solutions like EZ_SOP give manufacturers a practical way to implement visual SOPs for operators, enforce version control, and build a culture where procedures are actually followed. In a world where quality, safety, and compliance define competitiveness, the smarter choice isn’t more text—it’s better SOPs.

Software Solutions for Manufacturing Excellence

Company

Social

Our Contact Info:

Email: contact@orcalean.com

Phone Number: 248 938 0375

Our Offices