Why You Still Get Defects Despite Following Instructions

April 22, 2025

You’ve invested in SOPs. Operators have been trained. Audits say they’re following procedures. And yet—defects persist.

This frustrating disconnect is more common than most manufacturers admit. Everything appears to be under control… until scrap piles up or customers complain.

So what’s really going wrong?

This article explores why standard work compliance doesn’t always mean quality outcomes. You’ll uncover hidden execution gaps, systemic weak points, and practical ways to fix the flaws that written instructions alone can’t catch.

The Illusion of Control: Why Standard Work Alone Isn’t Enough?

Standard work is foundational in lean manufacturing. But over time, many factories develop a false sense of security around it. Managers assume that once SOPs are documented and operators are trained, quality issues should vanish. However, execution in dynamic environments like factories involves dozens of variables that written procedures alone can’t control.

When defects occur despite instruction adherence, it’s often because:

- The instructions lack clarity or fail to reflect actual process complexities.

- Operators execute mechanically but not mindfully, especially during repetitive work.

- Environmental or equipment-related variables introduce inconsistencies.

- Tribal knowledge and workarounds override formal SOPs.

Explore our blog that covers how to reduce defects in factory with advanced strategies.

Instruction ≠ Execution: Understanding the Gap

Let’s start with this truth: “Following instructions” is not the same as achieving defect-free execution.

Operators may be doing exactly what the SOP outlines, but:

- The SOP could be outdated.

- It may not include critical edge cases or product variants.

- There’s room for subjective interpretation, especially when steps are text-heavy.

- Visual guidance is missing or oversimplified.

Consider this example:

An operator assembling a wiring harness follows the instruction “connect blue wire to terminal A.” But on newer models, two different blue wires exist. The SOP doesn’t clarify which. The operator guesses—and a defect slips through.

Here, the problem isn’t non-compliance. It’s poor instruction design.

Hidden Root Causes: Why Instructions Aren’t Enough

Even the most well-intentioned teams can’t produce consistent results if the foundation is flawed. Below are the key hidden causes—along with what to do instead.

Poorly Written or Outdated SOPs

Even if an SOP is being followed, if it’s vague, obsolete, or cluttered, it becomes a source of variation. Operators end up filling the gaps with their own assumptions.

Example: Instead of “tighten bolt until snug,” say “tighten to 45 Nm using torque wrench.” Visuals and specificity matter.

Using excel and paper instructions makes data obsolete and difficult to track and update. Thus manufacturers are switching more towards digital SOP solutions that keep data centralized and easy to manage. Explore our blog that covers why modern manufacturers are switching towards digital solutions.

Tribal Knowledge vs. Documented Process

What’s written down often isn’t what’s actually done. Experienced operators rely on tricks learned over time—but those aren’t captured for others to follow.

Example: Don’t assume consistency. Capture those “unspoken” tweaks during shadowing and build them into the SOP.

Training Gaps

Two people can follow the same SOP and get different results. Why? Because comprehension, not just completion, matters. Training that’s rushed or too generic doesn’t equip workers for real-world variability.

Example: Replace one-time classroom sessions with hands-on, scenario-based training that checks for understanding.

Cognitive Overload and Fatigue

A task done correctly in the first hour of a shift can become error-prone by hour eight. Long routines, repetitive tasks, and mental fatigue reduce precision—even with SOPs.

Example: Break down long sequences into modular SOPs with built-in rest and verification steps.

Uncontrolled Variables

Even when the task is executed perfectly, inputs may vary. Tool wear, material inconsistencies, and ambient temperature shifts can all introduce defects that SOPs don’t account for.

Example: Add standard checks for machine calibration or part conformity at the start of the task—not just at the end.

Weak Escalation Culture

Many operators notice problems but don’t flag them—because it’s inconvenient, discouraged, or unclear who to alert. Problems then hide in plain sight.

Example: Instead of “report issues,” embed simple escalation triggers like color-coded checklists or digital alerts that route to supervisors automatically.

How to Diagnose the Real Problem?

Solving recurring defects starts with surfacing the true gaps between intention and execution. These techniques help reveal what’s really happening:

SOP Gemba Walks

Go to the workstation. Watch how the task is done vs. how it’s documented. You’ll spot mismatches that paper audits can’t catch.

You may find that a step marked as “quick visual inspection” actually takes 90 seconds—or is skipped entirely under time pressure.

Cross-Shift Comparison

Compare defect rates or execution styles across shifts. Differences often highlight training inconsistencies, tool calibration issues, or procedural ambiguity.

One shift might rely on visual feel, while another strictly measures. Same SOP—very different results.

Defect Pattern Analysis

Use defect logs to trace repeat issues to specific tasks, operators, shifts, or equipment. Patterns over time often reveal deeper process flaws.

If the same defect shows up every Thursday on Line 4, the cause may not be the operator—it could be the batch changeover or tool wear cycle.

Operator Interviews

Ask operators what’s unclear, what slows them down, and what they’ve adapted. Their lived experience reveals where SOPs don’t reflect reality.

You might learn they skip a step not out of laziness, but because it’s impractical with current tooling.

Watch for “Workarounds”

When people invent ways to “make it work,” that’s a red flag. It signals that the process doesn’t fully support reliable execution.

That clamp fixture missing a stopper? Operators manually align parts every time. It works—until it doesn’t.

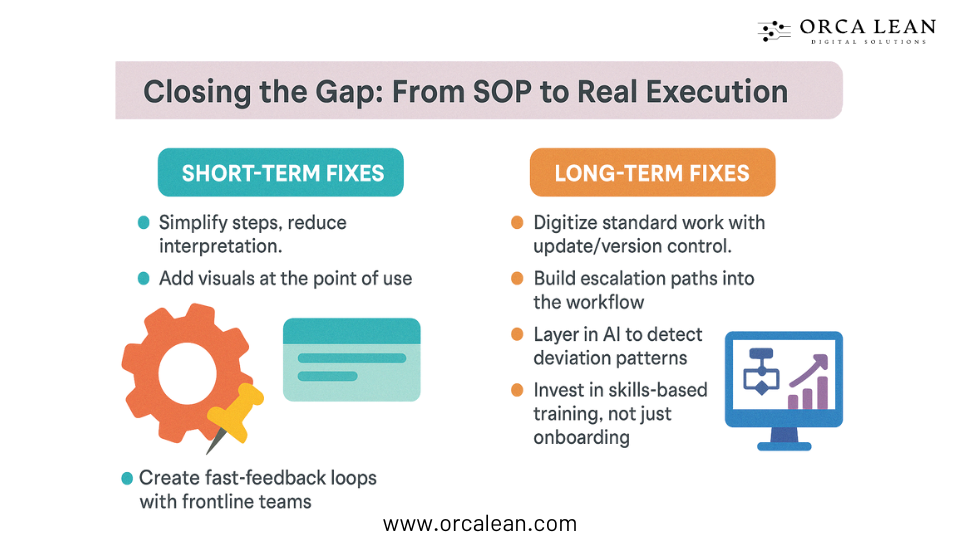

Closing the Gap: From SOP to Real Execution

It’s time to move from assuming SOP compliance equals quality—to actively designing systems that make correct execution easy, consistent, and observable.

Short-Term Fixes | Long-Term Fixes |

Simplify steps, reduce interpretation Use fewer words, clearer visuals, and unambiguous action verbs. Cut cognitive load. Rewrite “Inspect thoroughly” to “Confirm 3 red pins are fully seated and flush.” | Digitize standard work with update/version control. Paper SOPs don’t reflect live conditions. Use a tool like Standard Work Pro to update procedures in real-time and push changes across shifts instantly. A supplier change? Update the spec and notify all affected stations in minutes. |

Add visuals at the point of use. Position laminated diagrams, exploded views, or QR-code-linked videos right at the station. Instead of relying on memory, let the station itself reinforce the standard. | Build escalation paths into the workflow. Create structured ways for operators to flag deviations. Use visual boards, digital alerts, or even escalation buttons. Empower action, don’t just encourage reporting. |

Create fast-feedback loops with frontline teams. Set up daily check-ins or digital suggestion tools to capture issues before they become defects. If three operators flag the same confusing step, fix it this week—not next quarter. | Layer in AI to detect deviation patterns. Use Solvonext or other AI tools to analyze execution data and correlate with defect spikes. AI can surface weak steps no human reviewer would catch. Example: AI spots that errors increase when Task A is done immediately after Task B—suggesting a fatigue or focus issue. |

Invest in skills-based training, not just onboarding. Ongoing micro-training, digital refresher modules, and role-based content keep skills sharp and aligned with evolving SOPs. Rotate in new scenarios quarterly to build resilience to change, not just repetition. |

Conclusion: Solving the Right Problem

When defects show up despite SOP compliance, the problem isn’t your people—it’s the system they’re operating in.

Standard work isn’t just about having a document. It’s about creating an ecosystem where operators can succeed under real conditions—where instructions are clear, execution is visible, and feedback flows both ways.

With Standard Work Pro, you can digitize and version-control your SOPs, ensure frontline teams always have the most accurate instructions, and embed real-time updates, feedback, and escalation directly into the workflow. It’s built for manufacturers who are serious about execution—not just documentation.

Explore Standard Work Pro to bridge the gap between written standards and real-world performance—because true compliance means getting it right, not just following the rules.

Software Solutions for Manufacturing Excellence

Company

Social

Our Contact Info:

Email: contact@orcalean.com

Phone Number: 248 938 0375

Our Offices