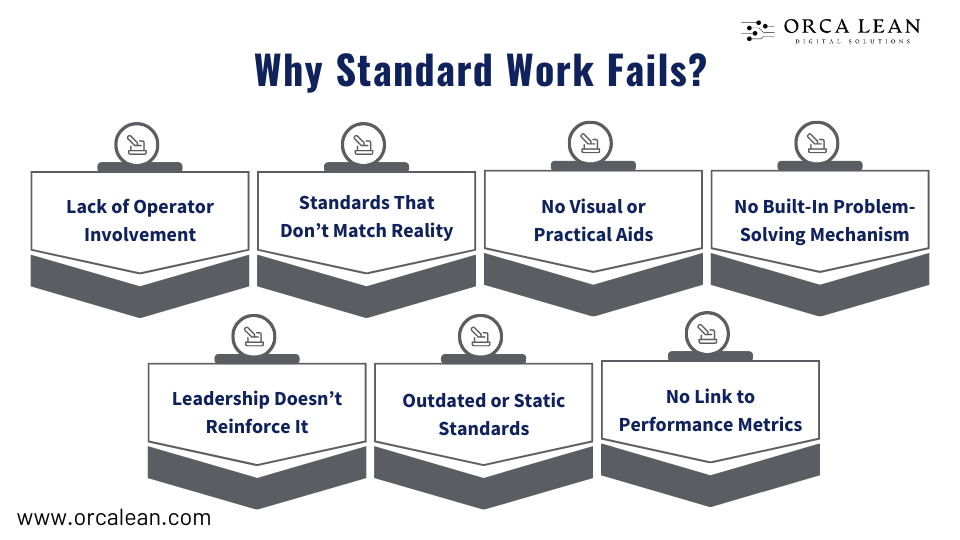

Why Standard Work Fails: 7 Root Causes and How to Fix Them?

April 9, 2025

Standard work is supposed to be the backbone of consistency and efficiency on the shop floor. But in reality? It often fails. Procedures are written but not followed. Audits happen, but nothing changes. The result? Frustrated operators, confused supervisors, and quality issues that keep resurfacing.

So, what’s going wrong?

In this blog, we’ll explore the 7 root causes behind standard work failure—drawn from real-world manufacturing experiences—and provide practical strategies to fix each one. Whether you’re a CI manager, quality lead, or plant supervisor, these insights will help you build standard work that actually works.

1. Lack of Operator Involvement

Problem: Standard work is created without input from the people doing the work.

Why it fails:

When engineers or CI teams create standard work in isolation, it often reflects an idealized process rather than reality. Operators—who know the process best—are handed procedures that ignore their experience, pain points, and constraints. This top-down approach leads to disengagement.

Operators feel like the standards are imposed by people who don’t understand the job. As a result, they either ignore the documentation or revert to tribal knowledge and personal methods. This kills consistency and undermines the purpose of standard work.

How to fix:

- Co-create standard work with operators.

- Capture actual best practices with video or live walkthroughs.

- Let operators suggest improvements during daily huddles.

For a deeper dive into this topic, read our full guide on how to engage shop floor workers to write and improve standard work. It includes proven strategies and real-world examples to help you make operator-driven standard work a reality.

2. Standards That Don’t Match Reality

Problem: The documented process doesn’t reflect how work is actually done on the floor.

Why it fails:

Processes change constantly—due to new machines, material variability, supplier issues, or updated customer specs. When the documented standard doesn’t evolve with these shifts, it becomes a dusty artifact. Operators ignore it because they know it doesn’t match what really works.

This disconnect causes inconsistency across shifts and increases the chance of errors, especially with new employees. Worse, audits based on incorrect standards give a false sense of control.

How to fix:

- Regularly audit how work is done vs. what’s documented.

- Capture real-time feedback on deviations.

- Use digital tools for factories to update standards dynamically.

3. No Visual or Practical Aids

Problem: Standard work is too text-heavy and hard to access during actual work.

Why it fails:

If an operator has to flip through a binder, open a PDF, or decode paragraphs while running a line—they won’t. On fast-paced floors, accessibility and clarity are everything. Written-only documents don’t help in high-noise, high-pressure environments. This leads to mistakes, skipped steps, and training issues. New hires especially struggle to learn the standard without visual cues or hands-on reinforcement.

How to fix:

- Convert text instructions into visual formats (photos, icons, videos).

- Display job aids at the point of use.

- Use mobile or screen-based tools to keep visuals accessible.

4. No Built-In Problem-Solving Mechanism

Problem: When deviations occur, there’s no standard way to escalate or react.

Why it fails:

Standard work assumes ideal conditions. But when something goes wrong—a bad part, missing tool, or jammed machine—operators are left guessing. Without a structured response, they may take shortcuts, improvise unsafe methods, or delay reporting the issue. This slows resolution, hides problems, and creates variability in how issues are handled across shifts.

How to fix:

- Include “if-then” escalation steps in the standard.

- Define who to notify and how.

- Use digital escalation systems for real-time alerts.

5. Leadership Doesn’t Reinforce It

Problem: Supervisors and managers don’t consistently enforce or model standard work.

Why it fails:

Leaders shape culture. If a supervisor ignores noncompliance or allows experienced operators to “do it their way,” it sends the message that standards are optional. Over time, this undermines accountability and encourages a culture of exceptions. Even well-written standard work falls apart when not supported by leadership presence and coaching.

How to fix:

- Conduct regular Gemba walks focused on standard work adherence.

- Train supervisors to coach, not just correct.

- Use leader standard work to reinforce daily routines.

6. Outdated or Static Standards

Problem: Once published, standard work is rarely reviewed or improved.

Why it fails:

Processes evolve, but paperwork often doesn’t. Teams improve their flow, remove waste, or adjust tools—but if documentation doesn’t reflect that, it becomes obsolete. Operators stop using it, assuming (often rightly) that it’s outdated. Worse, compliance audits become inaccurate, and training new staff gets harder.

How to fix:

- Set scheduled review dates for every standard.

- Empower operators to request updates.

- Use digital systems with version control and change logs.

7. No Link to Performance Metrics

Problem: Standard work is disconnected from actual performance outcomes.

Why it fails:

If operators don’t see how following the standard affects output, quality, or safety, they view it as a formality. Without visible cause-effect relationships, the work instruction becomes just another task to check off. That disconnect creates disinterest—and weakens commitment to consistent execution.

How to fix:

- Show how standard work impacts KPIs like defects, OEE, and rework.

- Review performance trends in team huddles.

- Reward teams for high adherence tied to measurable results.

Conclusion

Standard work doesn’t fail because it’s a bad concept—it fails because it’s poorly implemented, outdated, or ignored. When frontline teams aren’t involved, when leaders don’t reinforce it, and when standards don’t evolve with reality, consistency breaks down. But when done right, standard work becomes a powerful engine for quality, efficiency, and continuous improvement.

The fix isn’t more paperwork—it’s smarter, more collaborative, and digital-first systems that reflect how work actually gets done.

Standard Work Pro helps you build, deploy, and sustain standard work that your team actually follows. From visual instructions to version control and built-in escalation paths, we make standardization practical and powerful.

Ready to upgrade your standard work? Book a demo today.

Software Solutions for Manufacturing Excellence

Company

Social

Our Contact Info:

Email: contact@orcalean.com

Phone Number: 248 938 0375

Our Offices